40 Time Temperature Transformation Diagram

Make a copy of the isothermal transformation diagram for a $0.45 \mathrm{wt} \% \mathrm{C}$ iron-carbon alloy (Figure $10.39$ ), and then sketch and label on this diagram the time-temperature paths to produce the following microstructures: (a) $42 \%$ proeutectoid ferrite and $58 \%$ coarse pearlite (b) $50 \%$ fine pearlite and $50 \%$ bainite. DQ 5 DQ 0 z e2 E RT (6) where DQ 0 is a temperature-independent pre-exponential and E is the activation energy for diffusion. In equation (5), c* is the dimensionless concentration of Q defined by equation (7): c* 5 ~cQb 2 c Q i!/~c Q p 2 c Q i! (7) where cQ is the concentration of nonmetallic element in weight percent, the subscripts p, b, and i refer to the inclusion particle, bulk liquid.

The relationships between the extents of conversion at gelation and at vitrification and the isothermal cure temperature form the basis of a theoretical model of the time-temperature-transformation (TTT) cure diagram, in which the times to gelation and to vitrification during isothermal cure versus temperature are predicted.

Time temperature transformation diagram

Isothermal crystallization and time-temperature-transformation diagram of the organic semiconductor 5,11-bis(triethylsilylethynyl)anthradithiophene† Liyang Yu , * ab Andrew M. Zeidell , c John E. Anthony , d Oana D. Jurchescu c and Christian Müller * b The critical cooling rate can be estimated after depicting the time-temperature-transformation (TTT) diagram of an alloy 5. Therefore, it is necessary to establish a method to predicting the TTT. Time-Temperature-Transformation Diagram. An informative presentation of the silicone liquid rubber curing incorporating the degree of cure is the Time-Temperature-Transformation (TTT) diagram, developed by Enns and Gillham. It can be used to relate the material properties of thermosets, such as Silicone Liquid Rubber (LSR), as a function of.

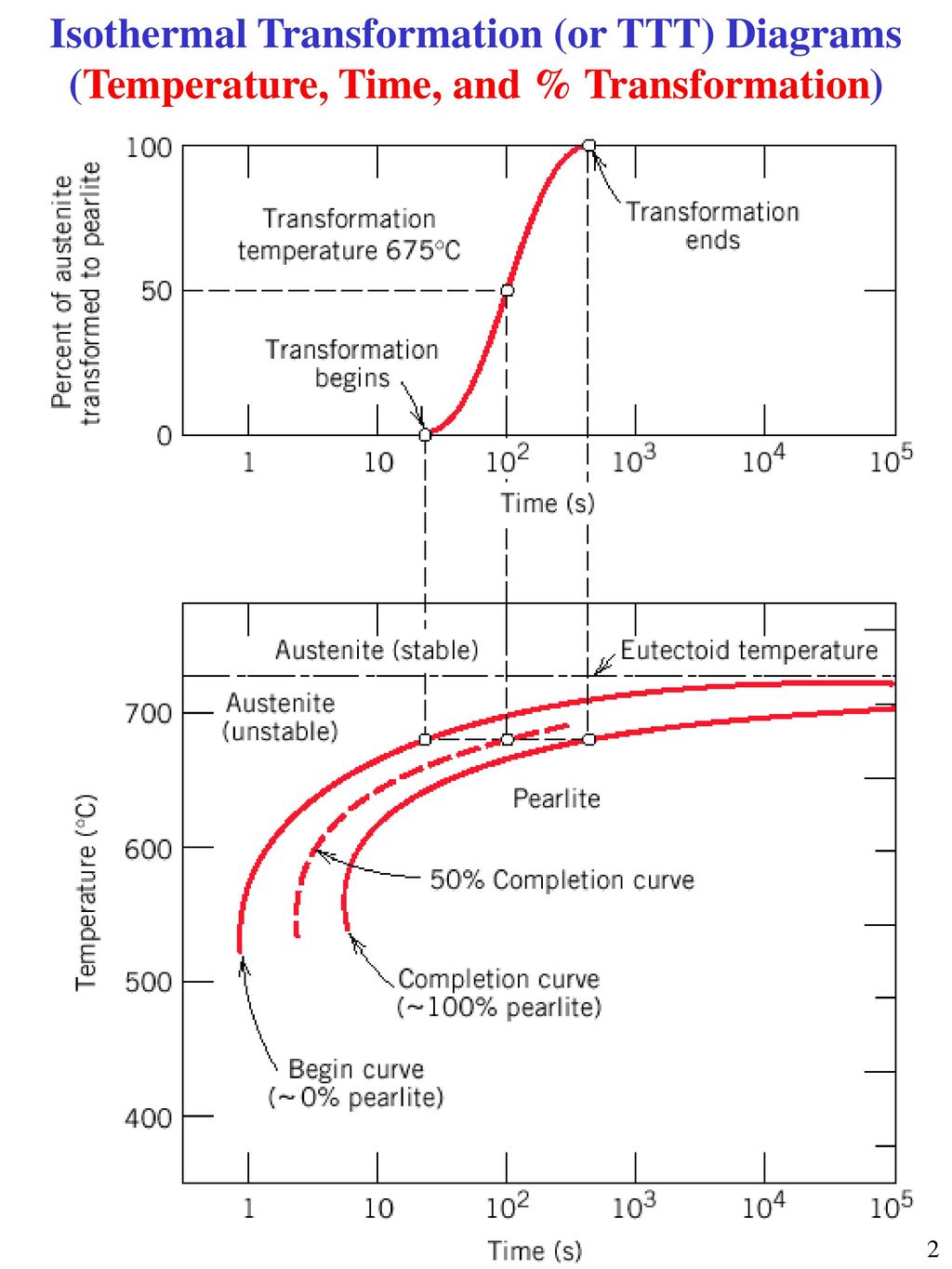

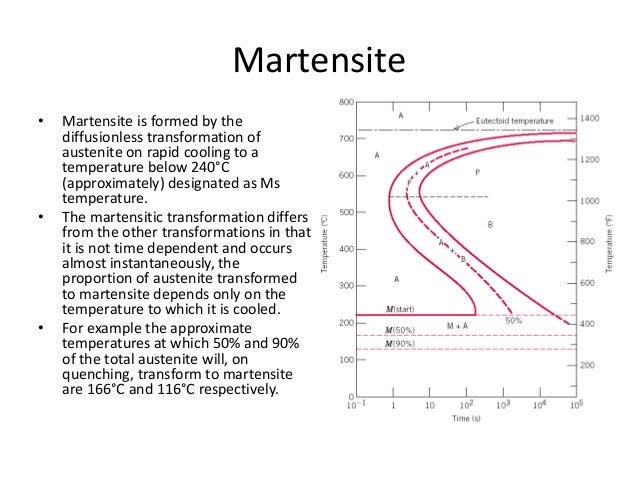

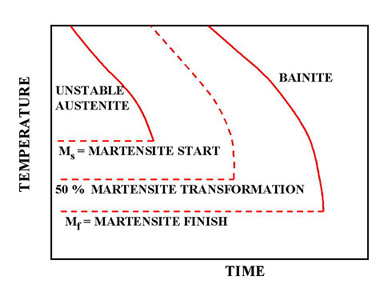

Time temperature transformation diagram. The time-temperature-transformation (TTT) diagram from Figure 12-20 is used to predict the _____ treatment required to obtain certain transformations of steel. tempurature Martensite is a phase that forms as the result of a diffusionless solid-state transformation, and this reaction depends only on __________. Time-temperature-transformation (TTT) diagram 10.18 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In Time-Temperature-Transformation (TTT) Curves TTT diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. TTT diagram indicates a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved.

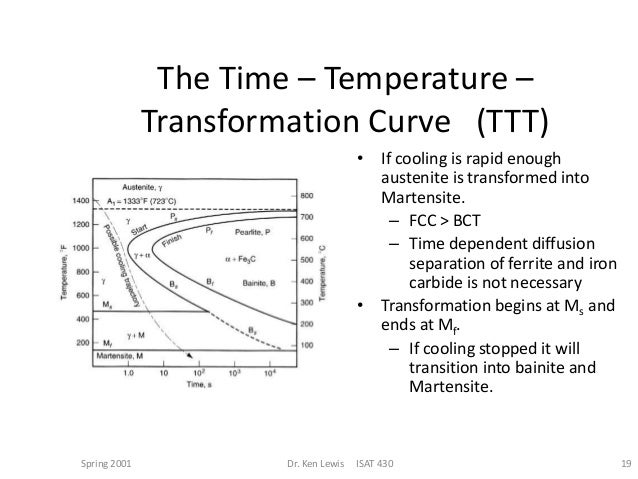

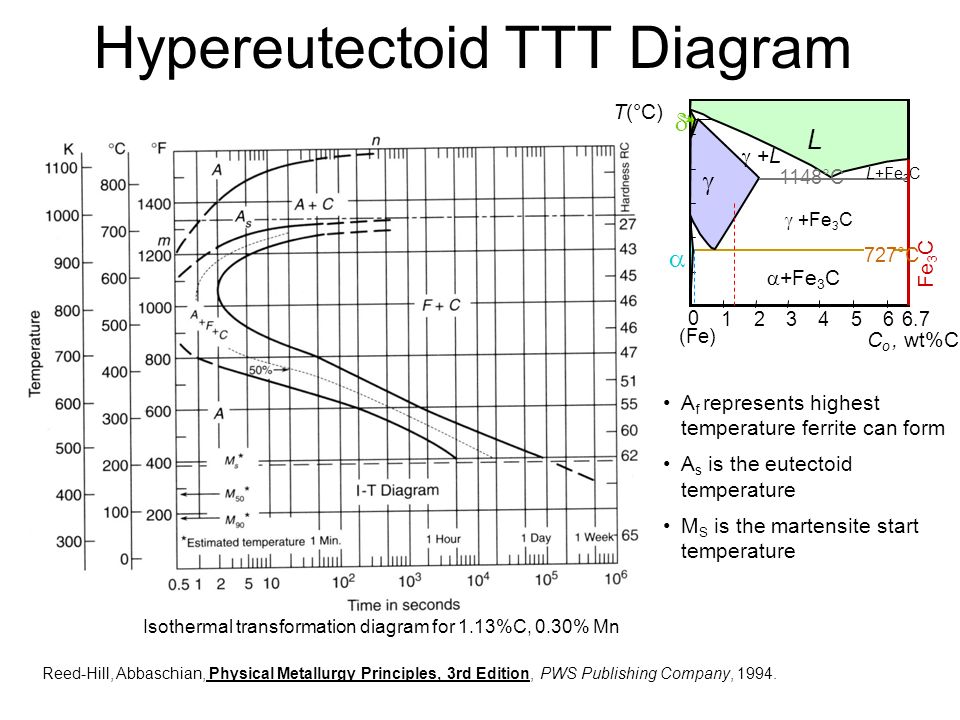

Time-Temperature-Transformation (TTT) Diagram. A good place to start an investigation into the hardenability of steel is with a TTT diagram. While a TTT diagram only acts as a rough guide, it will point you in the direction to search for high hardenability. High hardenability steel design means that the steel should have: (1) a high martensite. The critical cooling rate can be estimated after depicting the time-temperature-transformation (TTT) diagram of an alloy 5. Therefore, it is necessary to establish a method to predicting the TTT. Why TTT diagram is c shaped? We have mentioned before, TTT diagram is time and temperature transformation diagram.Pearlitic transformation is a diffusion-based transformation which involves solid-state conversion into alpha iron and iron carbide colonies. Without the required temperature and time, diffusion is not possible, and structure will, then, have martensite or bainite transformations. 2 Draw a typical T-T-T (Time- Temperature-Transformation) diagram for medium carbon steel and explain why it has a C shape curve. Explain the final microstructure of the steel under: a. Very slow cooling rate, to land above the nose of the "C" curves b.

Creation of time-temperature-transformation diagrams and what information we can extract from themLearning goals:- You describe the formation and occurrence. Isothermal phase transformation: The transformation of phase of an alloy with time occurring at a constant temperature. Fraction of transformation: The ratio of the volume of the transformed phase at any time and its final volume. t – time. α - parent matrix. β - precipitate. C. 0 - concentration of solute in matrix (far away from interface. The time taken to 1% transformation to, say pearlite or bainite is considered as transformation start time and for 99% transformation represents transformation finish. On quenching in water austenite transforms to martensite. But below 230 C it appears that transformation is time independent, only function of temperature. Therefore after Abstract. For the purpose of improving the processes of rapid heating and quenching of carbon steel, time-temperature-austenitization diagrams (T-T-A diagrams) were plotted for hypereutectoid steels (with carbon contents: 0.92, 1.28%). The dimension of specimen, preheat-treatments and experimental procedure were the same as in a previous report.

Changing the austenitizing time may also modify the transformation behavior, but this effect is much less. Knowing these limitations, the use of isothermal Time Temperature Transformation, and Continuous Cooling Transformation diagrams can be a great aid in planning and controlling the heat treatment of steel.

Time-Temperature-Transformation Diagram. An informative presentation of the silicone liquid rubber curing incorporating the degree of cure is the Time-Temperature-Transformation (TTT) diagram, developed by Enns and Gillham. It can be used to relate the material properties of thermosets, such as Silicone Liquid Rubber (LSR), as a function of.

time and temperature. TTT diagram shows the time required for transformation to various phases at constant temperature, and, therefore, gives a useful initial guide to likely transformations. In addition to the variations in the rate of transformation with temperature, there are variations in the structure of the transformation products also. Er.

TEMPERATURE 1000 C 800 C 727 C 0 С TIME ; Question: 1. (8 points) (a) Sketch the time-temperature-transformation diagram for 0.4 wt. %C steel. (b) On this TTT diagram, sketch and identify the cooling curves needed to produce the following microstructures: (1) proeutectoid ferrite + pearlite and (2) 100% martensite.

Isothermal crystallization and time-temperature-transformation diagram of the organic semiconductor 5,11-bis(triethylsilylethynyl)anthradithiophene† Liyang Yu , * ab Andrew M. Zeidell , c John E. Anthony , d Oana D. Jurchescu c and Christian Müller * b

Time temperature-transformation diagram. 1. MM: 304 Heat treatment Topic: Transformation diagrams Compiled for T.E, Metallurgy by Engr. Muhammad Ali Siddiqui Lecturer Department of Metallurgical Engineering NED university of Engineering and technology Email: muetali@yahoo 1. 2.

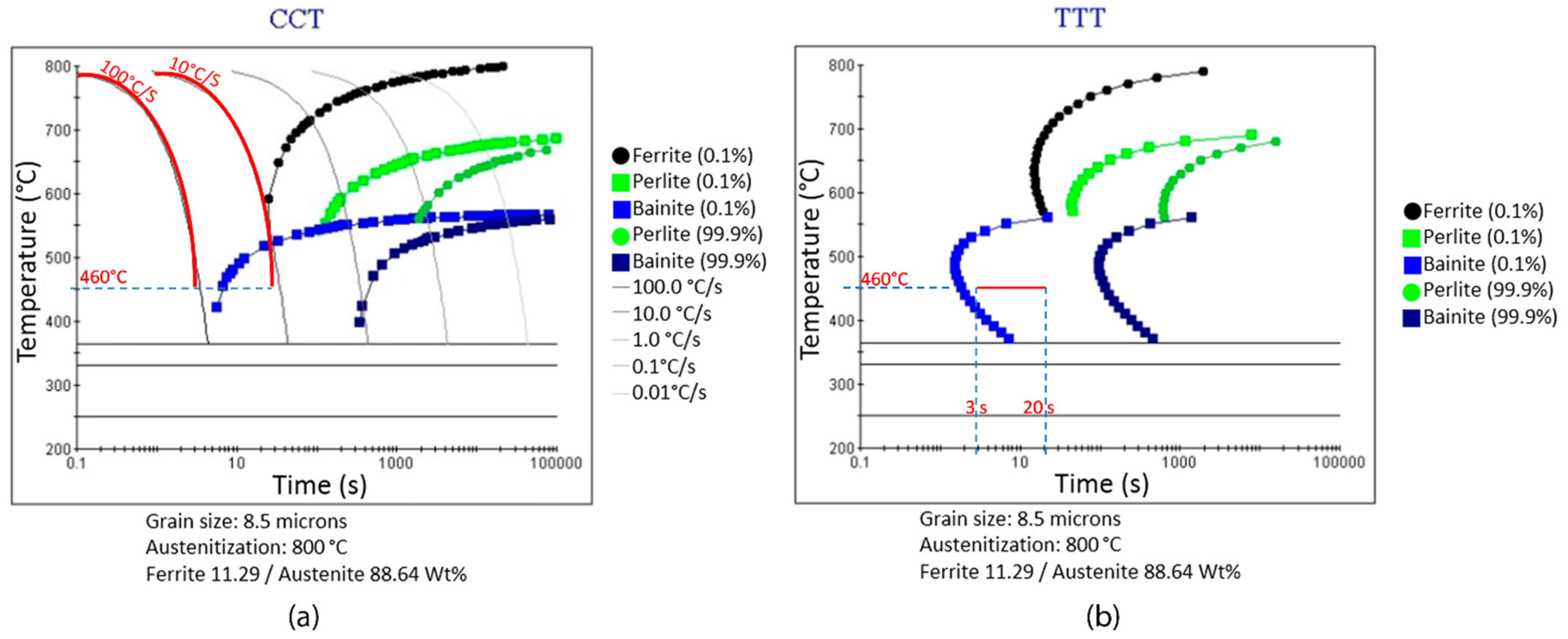

Figure 5: Diagram showing how measurements of the isothermal transformations of austenite as a function of time and temperature are used to create Isothermal TTT diagrams. Diagrams that describe the transformation of austenite as a function of constant temperature are called Time-Temperature Transformation diagrams.

Time - temperature - transformation (T-T-T) plots are also known as isothermal transformation diagrams. The sweeping curve going through the centre of the graph opposite is the transformation curve, which describes the extent of material which has changed through to pearlite.

Time-Temperature-Transformation (TTT ) Diagram T (Time) T(Temperature) T(Transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. It is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy.

It is not all that different from the unofficial TTT diagram for the pure iron above, except that the g ® a transformation temperature is now at 723 o C (1333 o F). Look up the phase diagram if you wonder about this. As before, we have an austenite region, stable above the transformation temperature A 1 at 723 o C.

Other articles where Time-temperature-transformation diagram is discussed: industrial glass: Kinetic arguments:.factors, the glassmaker generates a time-temperature-transformation (T-T-T) diagram. In this diagram a curve is plotted showing the heat-treatment times that would be required at various temperatures in order for detectable crystallization to occur.

Atlas of Time-Temperature Diagrams 3 Significance of the Isothermal Transformation Diagram When steel in the austenitic state is held at any constant temperature lower than the minimum at which its austenite is stable, it will in time transform. The course of isothermal transformation may be represent.

Time temperature transformation (TTT) diagrams, also known as isothermal transformation diagrams, predict phases and/or microstructure based on how the material is cooled. TTT diagrams have time on the x-axis and temperature on the y-axis. The lines on a TTT diagram represent points at which a material transforms from one phase or.

Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain's curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

Isothermal transformation diagrams (also known as time-temperature-transformation (TTT) diagrams) are plots of temperature versus time (usually on a logarithmic scale).They are generated from percentage transformation-vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures.. An isothermal transformation diagram is only valid for one.

The diagrams that illustrate the transformation of austenite as a function of time at a constant temperature is a TTT, or isothermal transformation (IT) diagram. In the simplest form (in plain carbon, or low alloy steels), these curves have a well-defined 'C' or 'S' shape.

(171).jpg)

0 Response to "40 Time Temperature Transformation Diagram"

Post a Comment