42 Brushless Motor Winding Diagram

Internal Connection Diagrams For Three Phase Electric Motors Resource Library Easa The Electro Mechanical Authority. No 13 winding diagram for an ac motor madcomics 3 phase connection all 15 reading a 24 slots of the single three motors electric diagrams generator series control devices induction wiring types handbook machines squirrel cage electrical csir part what is and its dc windings how. Recently, the flux-mnemonic permanent magnet brushless (FM-PMBL) motor is regarded as a promising traction motor for electric vehicles (EVs) due to its effective and efficient air-gap flux control.

The brushless wound-rotor doubly fed synchronous motor system has an independently excited rotor winding that does not rely on the principles of slip-induction of current. The brushless wound-rotor doubly fed motor is a synchronous motor that can function exactly at the supply frequency or sub to super multiple of the supply frequency.

Brushless motor winding diagram

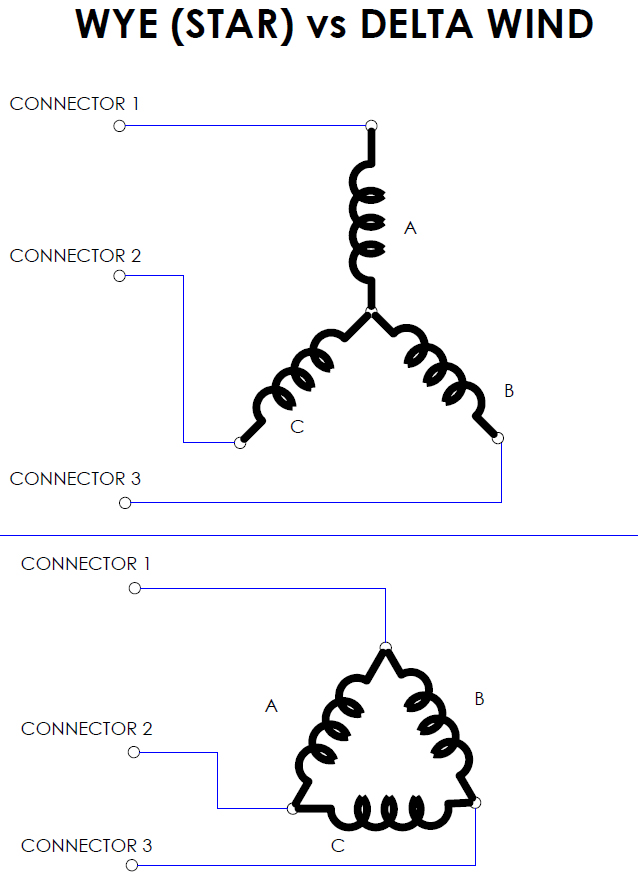

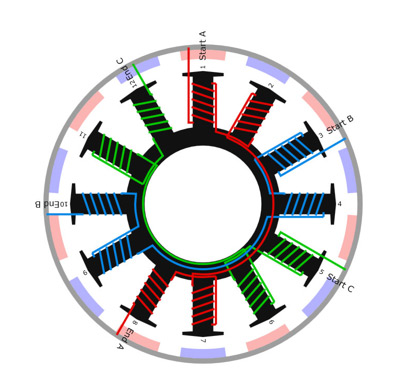

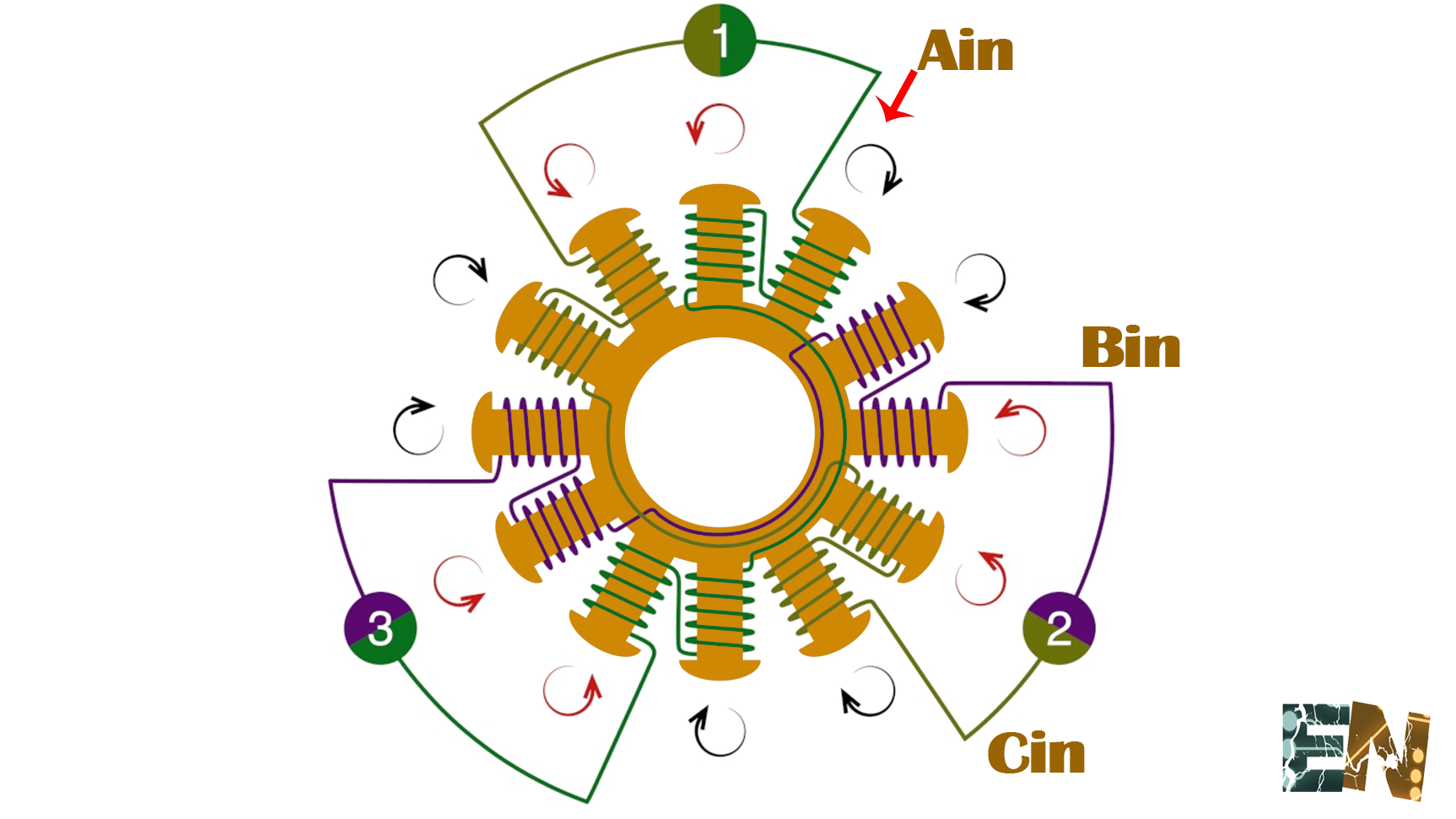

The stator is made of thin metal sheets and several windings of copper wire form electromagnets that can create magnetic fields that can be controlled by your ESC. For three phase brushless motors, the number of stator poles is always a multiple of three. In the case of the BR1103B you can count nine stator shoes. The number of magnets in the. Fig. 9 Block Diagram of AC Speed Control Motor System. Fig. 10 Waveform for Each Block. Fig. 10 shows the waveforms of each block. The speed set value d and the detected voltage e of the speed generated by a tacho-generator is compared in the comparison amplifier block.Then the level of the voltage signal a is determined. The voltage signal a is low when the speed detected value to the. Brushless motor winding. A picture is worth hundreds of words. Here is a wiring diagram for the star configuration that I have found from the net. you are better to do this with great circumspection or it would be easily end up with a burned ESC. The first photo shown above is one group of the windings on the stator.

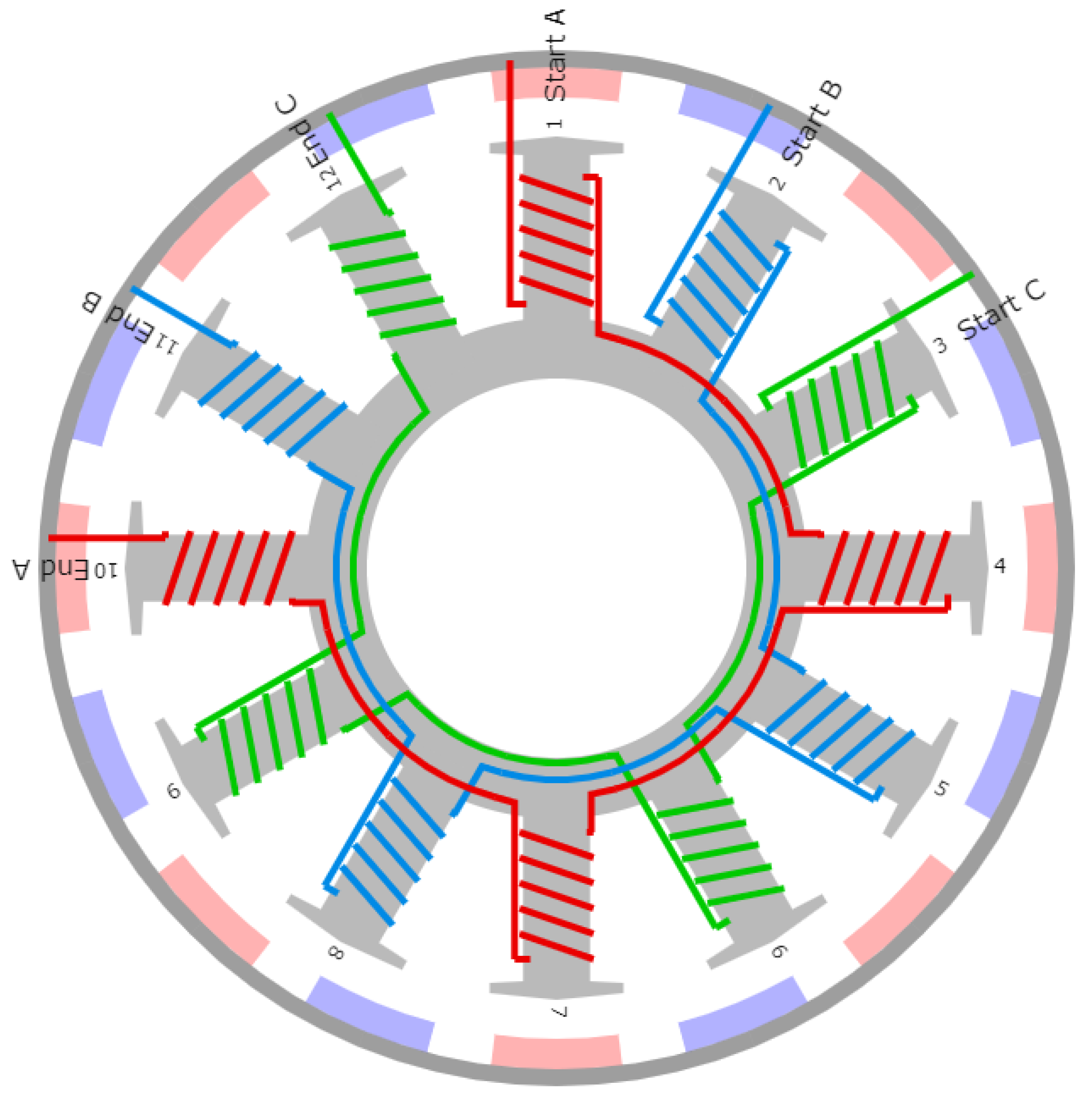

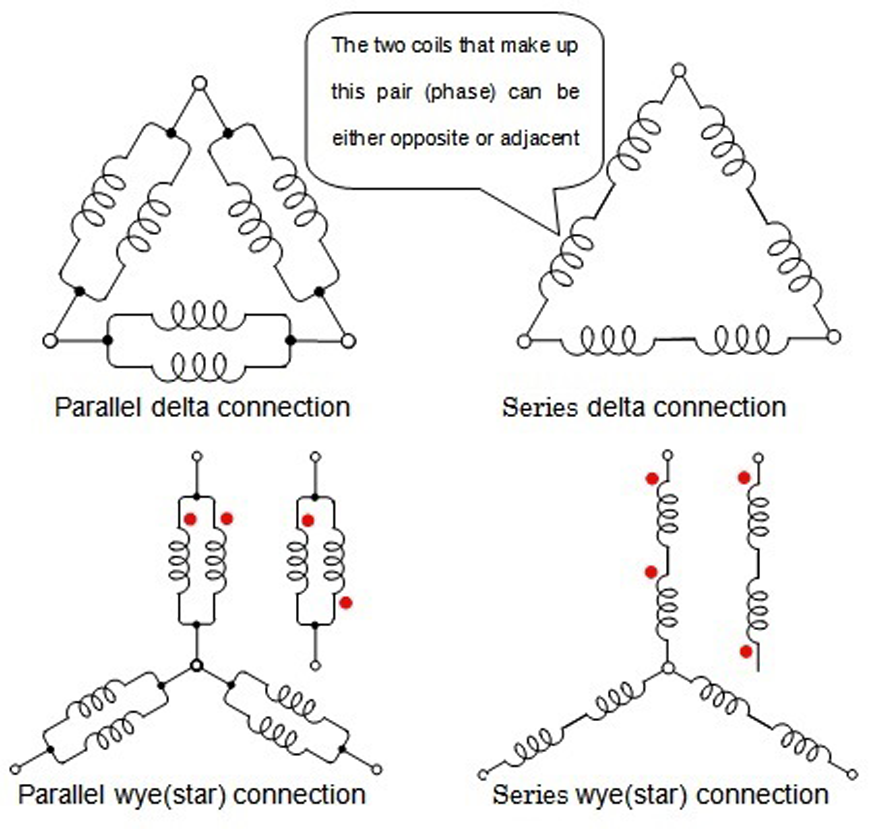

Brushless motor winding diagram. SINGLE SPEED MOTORS For delta ( ) wired motors For star ( ) wired motors Diagram DD1 Diagram DD2 Suggested wiring arrangement U1 U1 V1 V1 W1 W1 U2 U2 V2 V2 W2 W2 L1 L1 L2 L2 L3 L3 E E TWO-SPEED MOTORS with 2 separate windings (dual winding) High speed Red Leads Red Leads Black Leads Black Leads M 3~ Single speed only 3Ø WIRING DIAGRAMS U1. Brushless motor winding. A picture is worth hundreds of words. Here is a wiring diagram for the star configuration that I have found from the net. you are better to do this with great circumspection or it would be easily end up with a burned ESC. The first photo shown above is one group of the windings on the stator. You will need: brushless motor with a 12 tooth stator and 14 magnets 200-400 grit sandpaper Enamel coated wire Wire cutters Pliers I used a hexTronik DT or D40xx motor, They are great for this experiment because they are large, easy to rebuild, and can hold a wide range of wiring configurations that can handle around 150-650W and 400-2000kv. They work best on 2-4 cell lipo batteries with a 7. Jun 26, 2018 · The motor used in this application note has 12 teeth (poles) and 16 magnets. So, to make 1 turn we need to generate 48 electrical steps. Designing the 3-Phase Brushless DC Motor. The main block diagram and typical application circuit are shown in Figure 3 and Figure 4 respectively. Figure 3. Block diagram. Figure 4. Typical application circuit

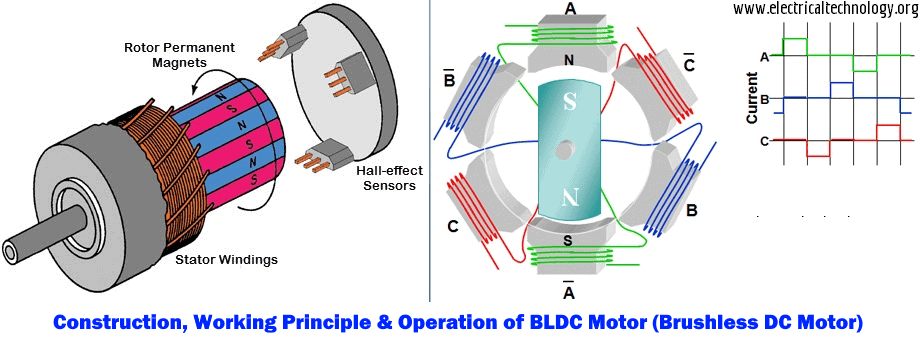

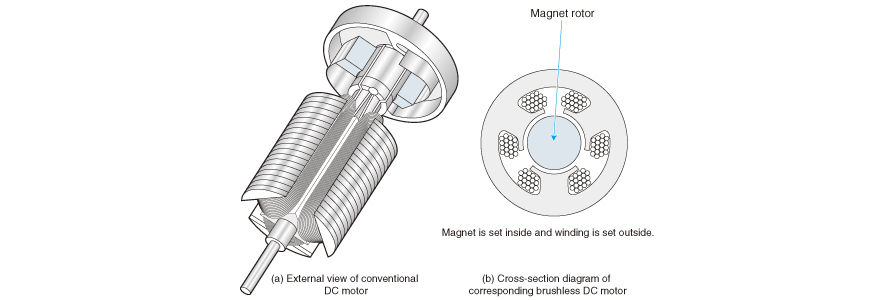

Brushless Motor Wiring Diagram Brushless Motor Winding Diagram 2eb99 Brushless Esc Wiring Diagram Digital Resources Industrial Grade Brushless Motors R4x Wiring Diagram Empire Amazon Com Zxtdr 48v 1800w Brushless Motor And Controller Mac 24 Volt 400 Watt Brushless Motor Wiring Manual From Rc Motor Diagram Wiring. Constructional Features of Brushless dc motor. Fig. 1 illustrates this type of motor with the help of a simple block diagram. In conventional d.c motor, field magnets are placed on the stator and armature winding is placed on the rotor. However, brushless dc motor has a polyphase winding (armature) on the stator and permanent magnets on the rotor. The stator is made of thin metal sheets and several windings of copper wire form electromagnets that can create magnetic fields that can be controlled by your ESC. For three phase brushless motors, the number of stator poles is always a multiple of three. In the case of the BR1103B you can count nine stator shoes. The number of magnets in the. motors, there are two basic winding stepper motor drives information Resistance-per-winding is another characteristic of a stepper motor. This resistance coil is divided in two. So the diagram above (Figure 3.65), which has two center-tapped coils, represents the 3.8.4 stepper motors Three-phase brushless motors offer many

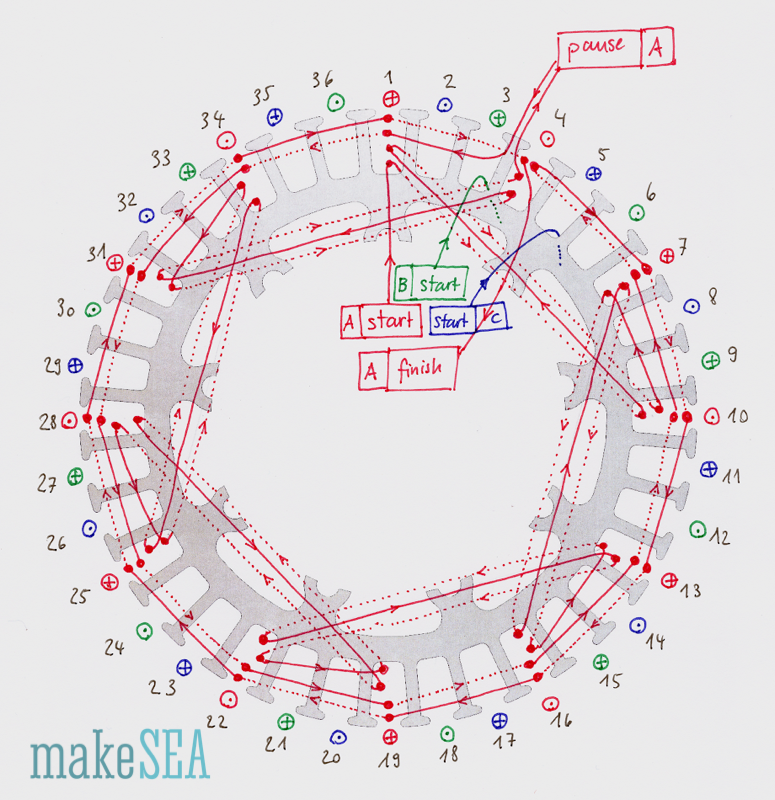

Brushless DC Motors K. Craig 5 • Windings – Consider the diagram of the elementary two-pole, single-phase stator winding. – Winding as is assumed distributed in slots over the inner circumference of the stator, which is more characteristic of the stator winding than is a concentrated winding. This stator needle winder is suitable for winding BLDC stator. It equips with servo system. It can automatically intert wire end, winding, arraying, indexing... You would expect that most existing brushless motors use slot/pole choices that produce the best performance but as we will find using computer analysis, this is not always the case. For example most (3) phase (4) pole brushless motors are designed using (12) slot laminations with a (3) slot pitch distributed winding. Here we see a winding diagram for a 3-phase AC induction motor or brushless PM motor (IPM), having 4 poles and 36 slots. This winding could in fact be used with any AC machine, including a synchronous reluctance motor or a wound-field synchronous motor or generator. In most respects it is a regular classical example, and the objective here is to review some of the features of the diagram and.

Brushless motors have become a popular motor choice for model aircraft including helicopters and drones.Their favorable power-to-weight ratios and wide range of available sizes, from under 5 grams to large motors rated at well into the kilowatt output range, have revolutionized the market for electric-powered model flight, displacing virtually all brushed electric motors, except for low.

Dec 07, 2016 · The brushless DC (BLDC) motor’s increasing popularity is due to the use of electronic commutation. This replaces the conventional mechanics comprised of brushes rubbing on the commutator to energize the windings in the armature of a DC motor.. Figure 4: Hall-effect sensor logic switch output and winding status timing diagram for three...

Fig. 9 Block Diagram of AC Speed Control Motor System. Fig. 10 Waveform for Each Block. Fig. 10 shows the waveforms of each block. The speed set value d and the detected voltage e of the speed generated by a tacho-generator is compared in the comparison amplifier block.Then the level of the voltage signal a is determined. The voltage signal a is low when the speed detected value to the.

Brushless Motor Disassembly and Rewinding.Turnigy 5208 rewinding 150 turns to 210 turns.Poles: 12N14PTermination: starThe wiring diagram and step by step in...

A brushless motor is constructed with a per-. the wound stator poles. FIGURE 1: SIMPLIFIED BLDC MOTOR DIAGRAMS Author: Ward Brown Microchip Technology Inc. N S A C a a b b c c B com com com N N S S 110 010 011 101 100 001 N S S N 6 3 4 1 2 5 A C B c b a com Brushless DC Motor Control Made Easy.... mutate the winding currents is by means of ...

and optimized for a Pittman N2311A011 brushless DC motor. Other motors were also tested to assure that the code was generally useful. Anatomy of a BLDC Figure 1 is a simplified illustration of BLDC motor con-struction. A brushless motor is constructed with a per-manent magnet rotor and wire wound stator poles.

Dc Motor Winding Diagram Pdf. Construction of dc motor your brushless dc motors bldc what are construction of dc motor electrical electric motor design basic tutorial. Permanent Magnet Dc Motor Its Applications Advantages Disadvantages Circuit Globe. Schematic Of 36 Slot 4 Pole Stator Winding Generated With The Bobisoft Scientific Diagram.

You are looking for a big Brushless DC Motor for your Electric Car or Powered Paraglider? I show you how to make the winding. The Rotor and Stator parts I ha...

48v Brushless Motor Controller Wiring Diagram from diagramweb . Brushless dc electric motors (bldc), also known as electronically commutated motors (ecms the controller provides pulses of current to the motor windings that control the speed and torque figure 4: You can put any mosfets channel n you need.

A brushed motor driver can be used to drive single phase brushless DC (BLDC) motors with a few minor modifications. In brushed motors, the brushes perform the commutation, physically changing the direction of the current as the motor rotates. In a BLDC system, the current direction is changed through the use of electronics.

During the brushless DC motor design phase, Portescap engineers aim to optimize the brushless motor torque. Motor torque is the amount of rotational force that a motor generates during operation. The key components involved in producing torque are the magnet, the winding and the flux path.

A very important part of winding a brushless motor is making certain that you can pack in the most amount of copper as possible. Doing so will increase the efficiency of the motor. These smaller diameter strands of wire will allow the windings to be packed very tight decreasing the amount of voids in the windings. Take a look at this motor below.

User Guide Gbxâ Brushless Motor Calculator Gobrushless Com. Handbook Of Electric Machines. Design Optimization And Analysis Of An Outer Rotor Direct Drive Permanent Magnet Motor For Medium Sd Electric Vehicle. No 13 winding diagram for an ac motor simulation technology electromechanical design jmag 45kw bushless motor design brushless motors.

of the permanent magnet brushless AC motor according to the winding method are analyzed. A motor of the same size was designed by nite element method (FEM) simu-. Winding diagram (a) Distributed winding diagram (phase A)(b) Concentric winding diagram (phase A) 5 International Journal of Pure and Applied Mathematics Special Issue 1809.

DELTA vs WYE (STAR) Termination. Theoretically, the ratio between Delta and Wye is 1.732 (square root of 3). However, in practise this number is closer to 1.8. Therefore, a motor with a given number of turns, terminated WYE, would yield ~1.8 times more Kt (torque per amp) than a similarly wound motor that is terminated Delta, while the Kv (RPM/volt) would be ~1.8 times lower.

Winding diagram depends on number of magnetpoles versus number of statorpoles. Manuals * Motor construction articles by Christo v.d. Merwe (nice motor colours ) www.bavaria-direct.co.za * Two motorwinding videos Keep in mind that CD-rom and (a)(d)lrk have different winding diagrams!!! Determined by #magnetpoles versus #statorpoles.

Motor winding similar to a brushless DC design; Manufacturing cost very low for mass production, when fully tooled;. If the turn insulation fails in a form-wound stator winding, the motor will likely fail in a few minutes. Thus the turn insulation is critical to the life of a motor. Low voltage tests on form-wound stators, such as inductance...

Jul 19, 2010 · The brushless DC motor is a synchronous electric motor that, from a modelling perspective, looks exactly like a DC motor, having a linear relationship between current and torque, voltage and rpm. It is an electronically controlled commutation system, instead of having a mechanical commutation, which is typical of brushed motors.

For this tutorial, I will be using Dynam E-Razor 450 Brushless Motor 60P-DYM-0011 (2750Kv). It is a Delta wound 8T (It means 8 turns) quad wind. The winding pattern described in this tutorial (called an ABC wind - ABCABCABC as you go around the stator) works for any brushless motor with 9 stator teeth and 6 magnets.

Sep 27, 2019 · Construction of BLDC Motor. The main design difference between a brushed and brushless motors is the replacement of mechanical commutator with an electric switch circuit. Keeping that in mind, a BLDC Motor is a type of synchronous motor in the sense that the magnetic field generated by the stator and the rotor revolve at the same frequency.

stator has the same number of windings. Out of these, 3-phase motors are the most popular and widely used. This application note focuses on 3-phase motors. Stator The stator of a BLDC motor consists of stacked steel laminations with windings placed in the slots that are axially cut along the inner periphery (as shown in Figure 3).

A brushless DC motor (known as BLDC) is a permanent magnet synchronous electric motor which is driven by direct current (DC) electricity and it accomplishes electronically controlled commutation system (commutation is the process of producing rotational torque in the motor by changing phase currents through it at appropriate times) instead of a.

Figure 1-1 shows the functional block diagram of the 3-phase BLDC motor operation. A BLDC motor has a rotor with permanent magnets and the stator contains the windings. 3 Phase Brushless Dc Motor 3 Phase Brushless Dc Motor Controller Brushless Esc Brushless Motors 3phase Inverters Sc Control Motor Electronics Circuit Construction of BLDC Motor. Bldc […]

0 Response to "42 Brushless Motor Winding Diagram"

Post a Comment