38 Air Compressor Dryer Installation Diagram

Le Lematec Air Compressor Filter, Water Separator, Air Compressor Dryer with Drain Valve, For Air Tools, Plasma Cutters, and Air Lines (ZN312) 4.3 out of 5 stars 307. $16.35 $ 16. 35. 5% coupon applied at checkout Save 5% with coupon. Get it as soon as Thu, Nov 18. FREE Shipping on orders over $25 shipped by Amazon. Below is a typical example of an air compressor setup diagram. Air Compressor Maintenance Plan. The most effective way to avoid breakdowns in the future is to have a preventive maintenance plan in place when the machine is installed. To learn more about the maintenance that needs to be performed and how often, view our basic maintenance.

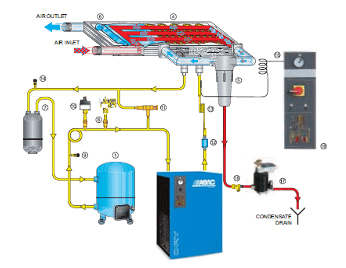

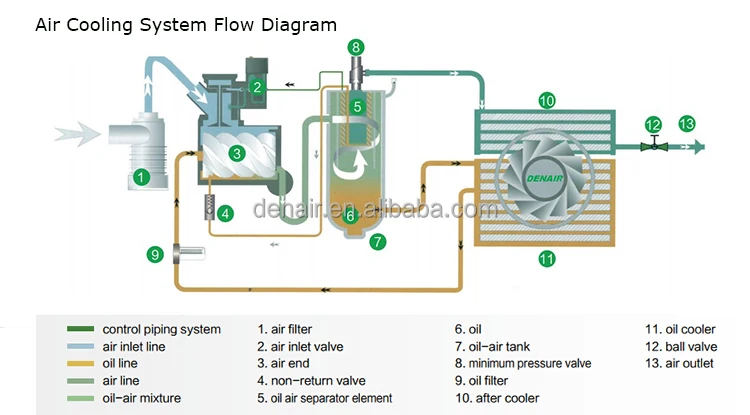

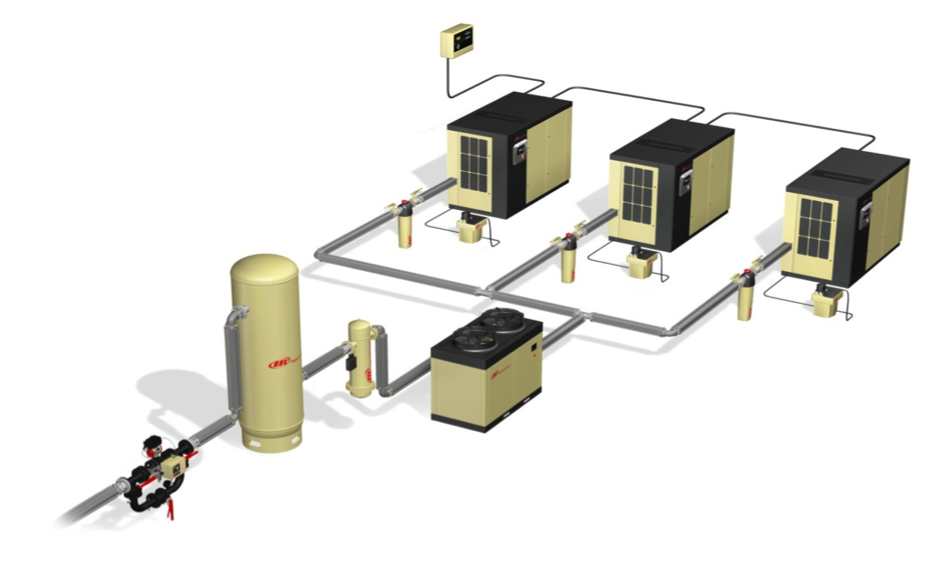

Compressor equipment installation diagram, which includes a dryer that is susceptible of being overloaded due to a poor piping design. Source: Motion Industries The trouble is that dryers have oversized components to reduce pressure loss across the equipment.

Air compressor dryer installation diagram

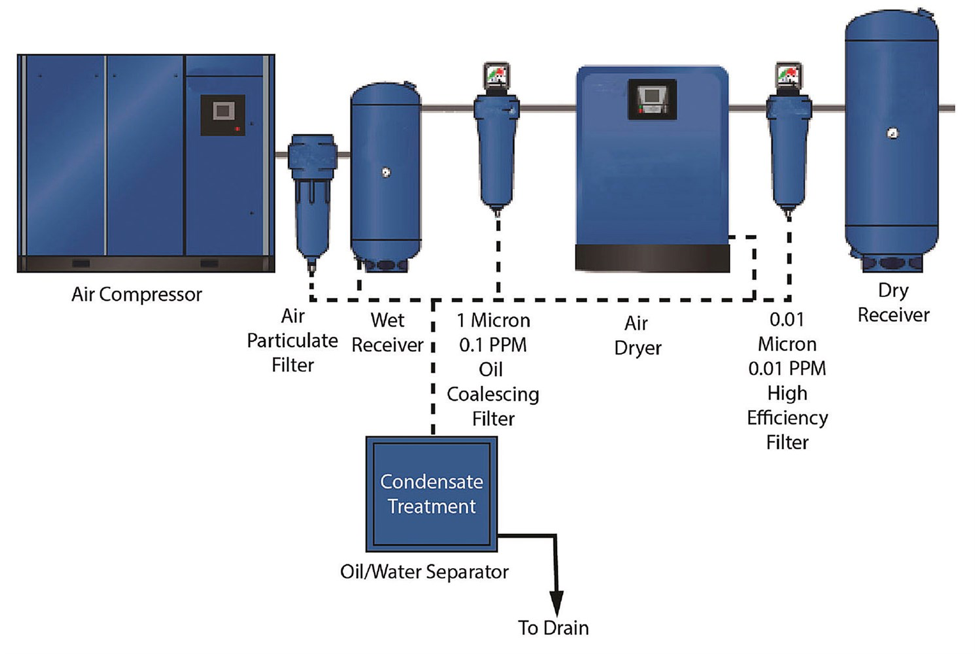

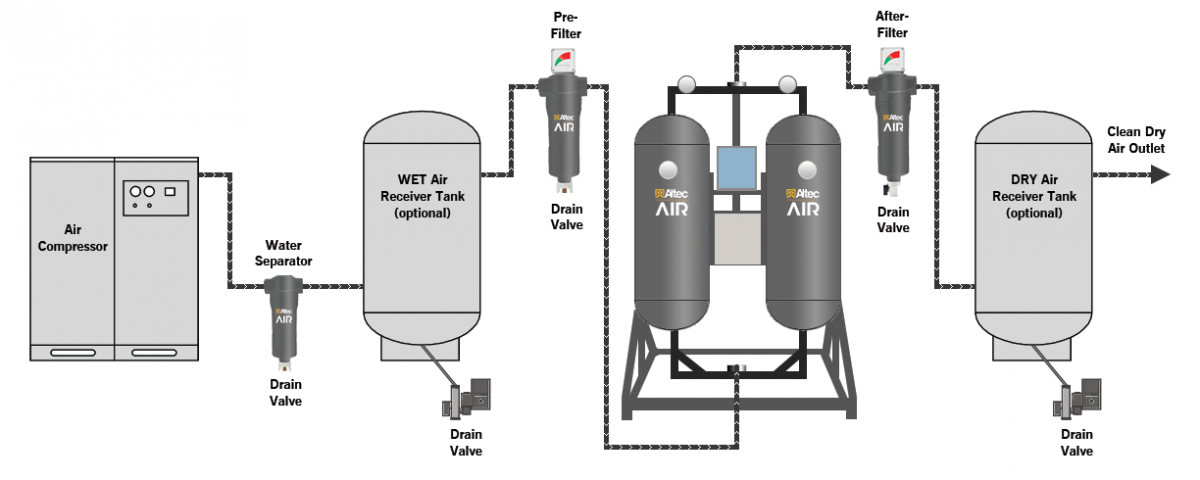

† The air dryer mounting method must be rigid enough to avoid vibration which could damage the desiccant or dryer. † The air dryer must not incline in any direction more than 15° from vertical position. † The air dryer must have at least 0.5 in (12.5 mm) free space above the cartridge canister to allow for removal during service. Refrigeration dryer energy costs (differential pressure) Direct electricity costs Energy cost savings SECOTEC refrigeration dryers require less than 100 W of electrical power per m³/min of compressed air (as per ISO 7183 A1). Thanks to its energy-saving control, surplus cooling performance can be stored temporarily in the ther- Air compressor After Cooler Section: The air passed through a aftercooler section where air temperature will be reduced & moisture will be condensates. Air compressor Receiver tank: It provides momentary reserve capacity, to improve regulation and to ensure a smooth flow through out the system.

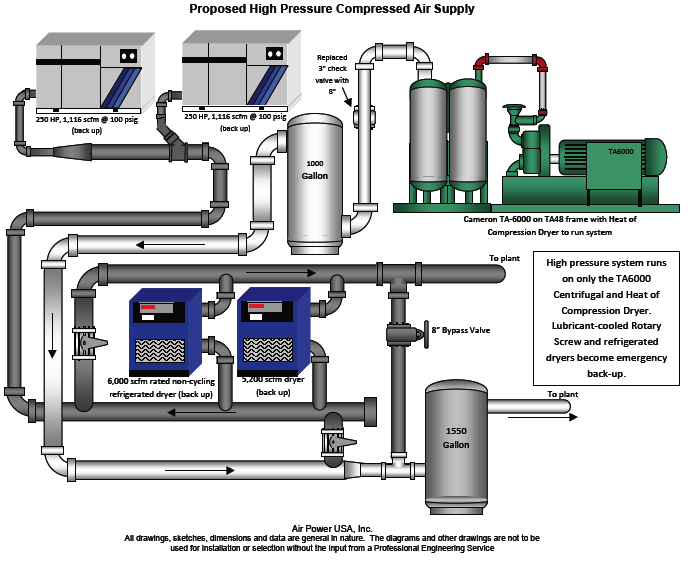

Air compressor dryer installation diagram. The most important quality of an air compressor is its cfm rating, which determines how much air is produced by the compressor. All pneumatic tools demand certain levels of cfm, and an air compressor must be able to meet all of the demands for the tools in your arsenal. For example, with a compressor rated 9.0 cfm, enough air will be generated. 1. A dry, well-ventilated area is the best location for installation of the dryer. It also should be in an area where the ambient temperature will not exceed 100°F (38C) or fall below 34° °F (1°C). 2. A flexible hose should be added between the dryer and the air compressor in order to prevent stress to the inlet heat exchanger Air compressor dryer installation diagram. Shutdown close the dryer air inlet valve and press the control button to shut then. When building a compressed air system it is common for many people to install an air compressor wire it up put a quick disconnect hose fitting on it. Air pressor wiring diagram 230v 1 phase download. 26.0 flow diagram 27.0 pressure switch adjustment 28.0 dryer calibration 29.0 voltage conversion - wiring diagram (on the back cover) important: a copy of the wiring diagrams can be found inside the electric board of the compressor. rotary screw compressor units hp 3 - 5 - 7.5 kw 2.2 - 3.7 - 5.5 machine and manufacturer identification data

Air from compressor and from Quincy Air Drying System, as equipped, is not safe for human respiration (breathing). • This dryer has been built to dry com-pressed air for industrial use. The dryer cannot be used in premises where there is a risk of fire or explosion or where work is carried out which releases sub-stances into the environment. Air compressor After Cooler Section: The air passed through a aftercooler section where air temperature will be reduced & moisture will be condensates. Air compressor Receiver tank: It provides momentary reserve capacity, to improve regulation and to ensure a smooth flow through out the system. desiccant air dryers can provide the correct air quality, without the need for drying the complete compressed air installation, which can be both costly and totally unnecessary. Sources of contamination found in a compressed air system Contaminants in a compressed air system can generally be attributed to the following: - Allow no open flame and flying sparks in the place of installation. - During any necessary welding on or near the compressor package ensure that sparks or high temperatures cannot cause fire or explosion. - Ensure that clean air without damaging impurities is fed to the compressor package.

At the vent of the air dryer, the regenerating air must flow out for approx. 10 seconds. Schematic for Testing and. Installation. Schematic 1: Schematic 2. Manual 35, Meritor WABCO System Saver TWIN Air Dryer. To obtain.. Check the entire air system for leaks, and repair as necessary. H. Connect electric power, according to the wiring diagram and nameplate power requirements, to the electrical terminals. The refrigerated dryer is designed to run continuously; therefore, it must be wired separately from the air compressor cycling switch. The dryer must not cycle with the air compressor. All units are prewired internally. Reduce the moisture within your air compressor piping diagrams by changing the supply inlet. This helps because water is heavier than air and drops to the bottom of the tank. Taking air from the top of a compressor means that the amount of moisture taken with it too is reduced. We also recommend that you have an aftercooler fitted with your. Big sandy recc paintsville ky 606 789 4095. This is simple to read and easy to use. Eimed60jmb dryer pdf manual download. I have a new sanborn 80 gal 240volt single phase 52 hp air compressor. Make sure you use this to check voltages before connecting. View and download electrolux eimed60jmb wiring diagram online.

FRL Filter Regulator Lubricator. Mist Eliminators reduce energy costs. Refrigerated Air Dryers. Non-Cycling Refrigerated Air Dryers. Energy Saving Series Refrigerated Dryer. Cycling Refrigerated Dryer. High Inlet Temp Refrigerated Air Dryers. Compressed Air Condensate Management. Electric Timed Drains.

Refrigeration dryer energy costs (differential pressure) Direct electricity costs Energy cost savings SECOTEC refrigeration dryers require less than 100 W of electrical power per m³/min of compressed air (as per ISO 7183 A1). Thanks to its energy-saving control, surplus cooling performance can be stored temporarily in the ther-

4. Plug in and turn on your compressor and you're ready to work without the Air Dryer. Using the Air Dryer without the bypass valve. 1. Before plugging in the compressor or the Air Dryer, open both of the shut-off valves. 2. Close the bypass valve. 3. Plug in and turn on the Compressor and Air Dryer. Shut-off Shut-off Electrical Installation.

Additionally, it can withstand compressor air flow out put of up to 80 CFM and up to 40 percent compressor duty cycle. The H.C. Dual Turbo-2000 includes the same internal filtration package as the standard Dual Turbo-2000 air dryer with 99.9 percent efficiency. • Proven effective by the country's largest and most severe-use municipal fleets.

Air compressor test system schematic solved fig 3 shows a diagram compressed systems energy engineering diy time delay circuit 2 storage tank control problem anantomy breakdown non cycling dryer flow schematics compressors scuba engineer wiring Schematic Diagram Of The Ejector Hybrid System 1 Air Compressor 2 Scientific Schematic Drawing Of The Compressor Test System Scientific Diagram.

PURest Air Dryer Installation and Maintenance L31170 Rev. 10/06 The Haldex PURest is a desiccant type dryer that effectively removes moisture, oil and contaminants from the compressed air system. This reduces the risk of freezing or corrosion of the components in the air system.

Precaution: Identify the air compressor circuit, turn it OFF and Tag it with a Note before working with the 220 volt air compressor wiring. Circuit Wiring for a 240 Volt Air Compressor. Circuit Size for an Air Compressor The circuit size will depend on the size of the air compressor and the horsepower rating of the motor.

Moisture in compressed air remains in a vapor state through the compression cycle, so it is not a problem until it leaves the compressor. n At 75°F (24°C) and 75% relative humidity, a 75 hp compressor takes in 46 gallons of water vapor in 24 hours. When this air is cooled to approximately 35°F (2°C) at 100 psig, the water vapor condenses

Compressor. Governor. (Governor plus Synchro valve for the Bendix® DuraFlo™ TU-FLO COMPRESSOR Air Compressor pdf manual download. Air pressure on the MANUFACTURED BY BENDIX inlet valve plus the force of the inlet. Their unloading mechanisms are located in the cylinder block and they have no external moving parts.

Air-cooled aftercoolers are commonly used with mobile air compressor systems because they are effective, easy to source, and relatively straightforward to install. Water-Cooled Aftercoolers Water-cooled aftercoolers do the exact same thing as air-cooled aftercoolers, only with more control of the discharge air temperatures.

How to install air compressor lines and air dryer for air compressor. You can buy the Air Dryer here: http://www.usaweld /Max-Dry-for-Plasma-Cutters-p/253...

Kaeser Wiring Diagrams Wiring Schematic Diagram 11 Laiser. Kaeser Es280 220hp Air Compressor. Kaeser Sigma Rotary Screw Air Compressor Air Dryer Package Dcm. Sam2 Sam2 User Manual Prodrive. Https Www Kaeser Com Int En Download Ashx Id Tcm 17 5981. Cccb Puma Air Compressor Wiring Diagram Wiring Resources.

Providing Industrial Air Compressor Service& Repair to Southern California. 24/7. Emergency Service. Available. Call Toll Free: 888.311.7247. Request A Quote / Information. Q Air-California is the premier supplier & distributor of industrial vacuum and compressed air systems, and accessories. Visit www.pumpengineering . The premier supplier.

The AD-IS ® air dryer and reservoir system is designed to receive compressed air from the vehicle air compressor, clean and dry the air, deliver air to the vehicle's primary reservoir, secondary reservoir and accessories, and control the compressor/dryer charge cycle. AIR DRYER AND RESERVOIR SYSTEM OPERATION: GENERAL

C. The air dryer has been installed in a system that has been previously used without an air dryer. This type of system will be saturated with moisture and several weeks of operation may be required to dry it out. D. Location of the air dryer is too close to the air compressor. Refer to Locating AD-9 ® Air Dryer On

1 A) When operating the air dryer the operator must apply safe working methods and observe all local safety instructions and relevant regulations. B) Prior to installation, the dryer and the compressed air system are to be depressurized and disconnected from the electrical main supply. C) The user is responsible for safe operating conditions.Parts and accessories must be replaced if inspection

1. A dry, well-ventilated area is the best location for installation of the dryer. It also should be in an area where the ambient temperature will not exceed 40°C or fall below 2°C. 2. A dryer should be kept at a distance from the air compressor in order to prevent

Assortment of ge dryer wiring diagram. A wiring diagram is a streamlined conventional pictorial representation of an electric circuit. It shows the components of the circuit as streamlined forms, as well as the power and signal connections in between the gadgets.

The air compressor on the Dry Air Pac® is designed to fill the sprinkler system with -40 to -60 degree F dew point air in 30 minutes in accordance with NFPA 13 standards, as well as provide the pressure needed to allow the air dryer to function properly. Prior to entering the desiccant beds, an air-cooled aftercooler cools the compressor's hot.

† The air dryer mounting method must be rigid enough to avoid vibration which could damage the desiccant or dryer. † The air dryer must not incline in any direction more than 15° from vertical position. † The air dryer must have at least 0.5 in (12.5 mm) free space above the cartridge canister to allow for removal during service.

0 Response to "38 Air Compressor Dryer Installation Diagram"

Post a Comment