43 incineration process flow diagram

Incineration - an overview | ScienceDirect Topics Incineration is a thermal waste treatment technique that can be understood as a controlled combustion process with the primary objective of volume reduction and energy recovery from the waste stream. Incineration is the most popular WTE technique, whereby heat produced from combustion can be recovered and converted to electric power [28,29]. The organic content of waste is combusted and heat is produced, whereas the inorganic content contributes to the formation of ash. Flue-gas stack - Wikipedia A flue-gas stack, also known as a smoke stack, chimney stack or simply as a stack, is a type of chimney, a vertical pipe, channel or similar structure through which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power plant's steam …

Explain the process of incineration, with the diagram. - TopperLearning Purpose of incineration: Reduces the volume of waste. Reduces the weight of waste. Converts toxic wastes into less toxic or even non-toxic substances. Impact of incineration: Releases fumes and harmful substances. Precautions to be taken for incineration: Incineration should be carried out at very high temperatures.

Incineration process flow diagram

Typical process flow diagram of waste to energy ... Download scientific diagram | Typical process flow diagram of waste to energy Incineration in Norway from publication: Multi-criteria decision analysis ... PDF INCINERATION WITH ENERGY RECOVERY - olc.worldbank.org Incineration with energy recovery refers to the combustion of waste under controlled . conditions to generate electricity and/or heat. The technology produces energy and heat, reduces the volume of municipal solid waste (MSW) that must be handled and destroys harmful substances, provided that the process includes highly advanced air pollution complete process flow chart of ferro chrome plant A typical scheme for an incineration plant operating on real waste and with energy recovery is given in Fig 1 Fig-1 Flow chart of incineration process The collected material is located in a land site and from here taken to be sent to the incineration process, normally performed in grid or rotating kilns The gas coming from the... Know More

Incineration process flow diagram. 3 Incineration Processes and Environmental Releases - NCBI Bookshelf Furnace Types. Table 3-2 lists the types of furnaces used for municipal solid-waste, hazardous-waste, and medical-waste incineration. Municipal solid-waste furnace designs have evolved over the years from simple batch-fed, stationary refractory hearth designs to continuous feed, reciprocating (or other moving, air-cooled) grate designs with waterwall furnaces for energy recovery. Spray drying - Wikipedia Spray drying is a method of changing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals, or materials which may require extremely consistent, fine particle size. Air is the heated drying medium; however, if the liquid is a flammable solvent such as … The schematic flow chart of MSW incineration process Figure 4 displays the schematic flow chart of the MSW incineration process. Incineration is a type of thermal WtE technology that can greatly reduce the volume ... schematic process flow diagram incineration msw ash diagram process schematic sustainability environmental figure. Process Flow Diagram Pg . pupuk alir sulfat asam amoniak. ... Process flow diagram water treatment flowcharting professional software visit osha rff. Flow pfd. Random Posts. Sg3524 Pwm Inverter Circuit Diagram;

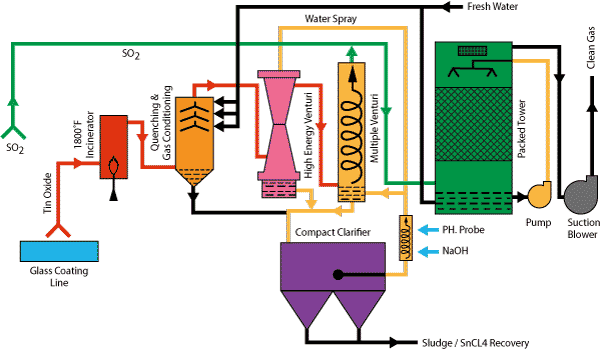

Process flow diagram of the incineration system. Its flow diagram is shown in Fig. 1. In this system, solid LW is fed through a feeding unit into an incinerator with two chambers. In the primary incineration chamber, the combustion temperature is... Fume Incinerator System Process Design Package Preparation The process design project included completion of the following tasks: Process design basis development, including vent stream characterizations. Regulatory design basis development, including required control system removal efficiencies. Process mass and energy balance computer simulations. Process design, and process flow diagram (PFD) and ... How Waste Incineration Works - Earth911 The general process followed in a mass burn incinerator includes five steps. Waste preparation: Oversized items are removed and certain recyclables like metals are recovered. The remaining waste is often shredded before it enters the incinerator. Combustion: Waste is burned in an oxygenated single combustion chamber. Grate Type Incineration | Waste Treatment | Solution | Kobelco Eco ... Process Flow Diagram Overview Our grate type incineration is equipped with a rotating furnace that efficiently mixes, stirs and incinerates waste. With the furnace walls consisting of boiler water tube walls, the facility also boasts a simple and solid structure with a relatively low number of moving parts. Features 1. Versatile

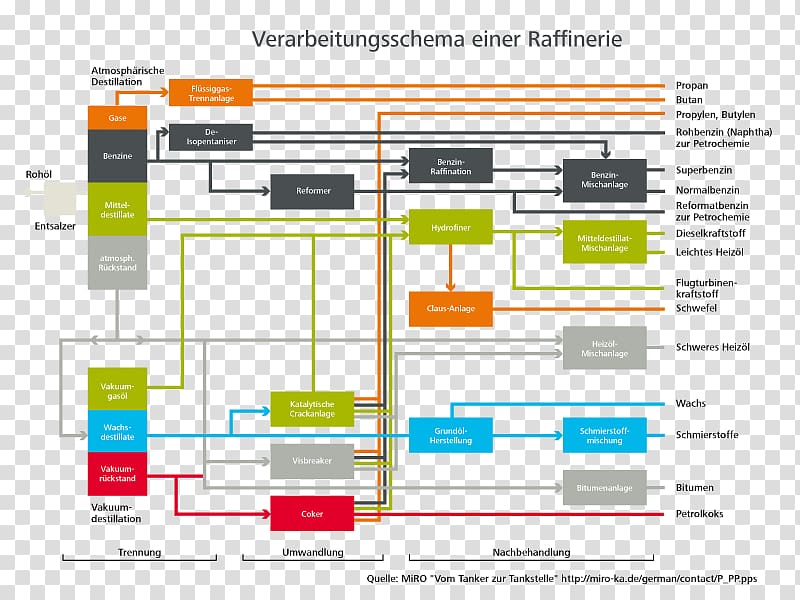

Incineration Process : Incinerator for Solid Waste, Bio ... - YouTube Incineration Process : Visit For More Details. Incinerator for Disposal of Solid Waste, Bio Medical Waste, Medical Waste, ... Gas treating and processing - PetroWiki 09/12/2021 · Free of dust, treating chemicals, and other contaminants from the process plant. In long distance transmission of sales gas by pipeline, the pressure is usually less than 1,000 psig. It is important that no liquids form in the line because of condensation of either hydrocarbons or water. Hydrocarbon liquids reduce the pipeline efficiency and might hold up in the line to form … Petkim Petrokimya Holding A.Ş. Last Update : 18.08.2022 - 23:24 Share: Price: Rate of change % PETKM: 11,06: 3,0755 » Annual report » Detailed share info Legal Notices and Conditions of use ... Environmental permitting guidance: waste incineration - GOV.UK Chapter 2 applies to a waste incineration or waste co-incineration plant if it has a capacity: more than 10 tonnes per day of hazardous waste. more than 10 tonnes per day of animal carcasses. more ...

Incineration - SlideShare Incineration. 1. BY LECTURER AKASH BAJAJ VISHWESHWARAYYA POLYTECNIC, ALMALA (DIST. LATUR) INCINERATION AND PYROLYSIS. 2. INCINERATION. 3. Introduction of incineration process Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste, and may take the form of solid lumps or ...

Utility systems - processdesign - Northwestern University 22/02/2016 · In the diagram above, boiler feed water at a high pressure is preheated and fed to other boilers. These other boilers superheat the steam to create a high pressure and high temperature steam stream. The steam is superheated past the dew point to account for heat loss in the pipelines. A portion of the high pressure steam is used for process heating in areas of …

Flow diagram of the incineration process in Spain and ... Outside of the system boundaries, steel is produced with scrap. Ash is solidified with a mixture of water (30%), cement (20%), and ash (50%) to produce an inert ...

Municipal Solid Waste Incinerator Design: Basic Principles 3. Factors Affecting Incineration. A good combustion process depends on the waste repartition on the grate, the effectiveness of the waste mixing to allow for a good contact between the combustible and air, a sufficient temperature in the drying-pyrolysis zone (primary air pre-heating and intense radiation) as well as a sufficient post combustion chamber temperature.

Waste Treatment With Incinerator - PPLI The flow diagram of the incineration process with a vertical stocker type incinerator is illustrated in the following figure: From the processing of the incinerator, bottom ash and fly ash will arise in the amount of about 10-20% of the burned waste. The bottom and fly ash will be disposed in secure landfill. Periodically, the characteristics ...

Electric Arc Furnace Process - an overview - ScienceDirect Fig. 2.1 is a flow chart to present the iron- and steelmaking processes and the types of slag ... the remaining 25% of the raw materials is steel scrap. EAF process uses 100% steel scrap in general, however, in some plants significant share of direct reduced iron (DRI) is used. Further, solid pig iron is used as “pure” raw material and carbon source in EAFs. The blast …

Waste to Energy (Incineration) Wholesaler - Dezhou Qunfeng Machinery ... WTE Incineration plant working flow diagram: This interactive graphic explains how the Waste to Energy plant works. It has been open since 2014 and operating at full capacity since day one. ... This process dries the waste and provides the correct amount of air to allow good combustion of the waste. Secondary swirling air is introduced above ...

0 Response to "43 incineration process flow diagram"

Post a Comment