43 air compressor plumbing diagram

Guide to Compressed Air Piping Systems | Quincy Compressor Water resulting from compression comes from air drawn in by your compressor. All ambient air has a certain level of humidity. When that air is compressed, the water in it condenses from its vapor form into a liquid state. There is a simple way to reduce moisture in the piping system : change the compressor's supply inlet source. Air Compressor Piping Diagrams and Tips | Tools Haunt An air compressor piping diagram is created by connecting an air compressor to any end-user tool through the use of a pipe. As simple as it may sound, creating your own piping diagram at home is rather a complicated process. Besides, you need the specific requirements of your project to come up with the correct piping.

How to Plumb an Air Compressor Setup in Garage - Ultimate Shop Air ... Air Compressor Plumbing Setup Tools. Before actually starting your compressed air plumbing setup, it's a great idea to familiarise yourself with and obtain the common plumbing tools you'll need to help you with the setup. Having a good range of quality tools will make the whole task a lot simpler and ensure you're doing the right thing.

Air compressor plumbing diagram

PDF Compressed Air System Standard Piping Diagram - Veterans Affairs Compressed Air System Standard Piping Diagram Author: Department of Veterans Affairs, Office of Acquisition Logistics and Construction, Office of Construction and Facilities Management, Office of Facilities Planning, Facilities Standards Service Subject: Standard Detail Created Date: 10/26/2017 1:02:30 PM Compressed Air Basics - Piping - Air Compressor Works, Inc. Compressors squeeze a lot of water out of the air. A filter will only get out some of it. If you don't have a dryer, more water will condense in your pipe. This water has to go somewhere - either it will get into your equipment or it will flow back into your compressor. A drip leg will catch this water. Compressor Piping Layout: Compressor Piping Design (With PDF) Fig. 2: Grade mounted Centrifugal Compressor Compressor Piping Layout Suction & Discharge Piping (Fig. 3) Compressor Suction Piping Shall be as Short as Possible. Compressor Suction Piping should have Inlet Filter / Strainer. It can be Temporary or Permanent Suction Piping should be sloping/free draining towards Inlet Scrubber

Air compressor plumbing diagram. How to set up air compressor air piping - YouTube Here is a quick video on how to setup your air compressor air piping. I used black pipes and ran it along my garage wall. I used a pressure regulator, water ... Connecting Two Air Compressors Yes, by adding a second air compressor you now have the addition of two air compressors CFM ratings. If the compressors were the same rating, you would have double the CFM. It may be that you have an 8 CFM air compressor and you add a 5 CFM air compressor, so you're resulting combined CFM will equal 13 CFM (8 + 5). Air Compressor Piping Diagrams and Tips - Home Tool Guides Top Tips for your Air Compressor Piping Diagrams Be sure to use a pipe cutter to cut steel pipes and a hacksaw for plastic pipes. The cut edges of steel pipes are very sharp. You can hold them in a small vice and cut the pipes with a pair of wire cutters. Insulate your piping to avoid condensation. Use pipe insulation or foam pipe wrap. Air Compressor Piping Diagrams And Tips - toolstext.com An air compressor is a machine used to increase the pressure and volume of air. The compressor is typically composed of a motor, a compressor wheel, and piping. The motor powers the compressor wheel, which in turn compresses the air. The compressed air is then distributed through the piping to various parts of the machine. 2. Piping and Tubing

How I Setup My Air Compressor Lines & Installing Air Dryer - YouTube How to install air compressor lines and air dryer for air compressor. You can buy the Air Dryer here: ... Senco PC1010 1/2 HP Electric Air Compressor Parts Need to fix your PC1010 1/2 HP Electric Air Compressor? Use our part lists, interactive diagrams, accessories and expert repair advice to make your repairs easy. Wiring & Plumbing Diagrams - VIAIR® Corp VIAIR recommends that you reference the chart below in order to determine the length and gauge of wire when installing your compressor. AMERICAN WIRE GAUGE (AWG) FOR 12-VOLT CIRCUITS AMERICAN WIRE GAUGE (AWG) FOR 24-VOLT CIRCUITS Download PDF Version Plumbing Diagrams: Compressor - Wikipedia A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor. Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. The main distinction is that the focus of a compressor is to change the ...

SimplAir Compressed Air Piping | Ingersoll Rand Simplair® piping is available in a wide range of outer diameter sizes from 3/4" to 8" (20 mm to 220 mm) to serve nearly any application. High-quality, all-metal, easy-to-install fittings make it easy for users to design and construct their own systems without the need for professional installers. Parts of An Air Compressor Diagram Guide - Air Compressor ... Feb 08, 2019 · The AC cord of the air compressor is how you supply electricity (power) to your motor by plugging the cord into a suitable wall socket. Most compressors are designed to run on either 120 volts or 240 volts. Some people opt for an extension cord so that they can place the air compressor in their preferred location (away from a power supply). Shop Air Compressor System Design & Plumbing [Complete Guide] There are several approaches to choose from when it comes to plumbing. You could use copper tubing, sweat soldered together. I have seen the majority of good home air systems done this way. Another approach is threaded black pipe. This is the strongest approach in terms of its ability to handle pressure. Air Compressor Piping Diagrams and Tips - Best of Machinery When there are lots of sharp angles in an air compressor piping diagram, the following happens: The speed of air slows down The flow of air is interrupted The pressure decreases Just like when you're driving, you must decrease your speed if you need to make a sharp turn. The same applies to air in an air compressor pipe system.

Air Compressor Piping Diagrams and Tips From Experts Feb 03, 2019 · One technique would be changing the supply inlet from the bottom to the top of the compressor, to help reduce the moisture. Another would be using an aftercooler, they can remove above 50% of the liquid in an air compressor piping diagram. It must be noted, that it is impossible to keep any air compressor system free of moisture.

Air Compressor Installation Guide - Tips & Setup Diagram Below is a typical example of an air compressor setup diagram. Air Compressor Maintenance Plan The most effective way to avoid breakdowns in the future is to have a preventive maintenance plan in place when the machine is installed. To learn more about the maintenance that needs to be performed and how often, view our basic maintenance checklist.

Air Compressor Piping Diagram [j3nojx1y7eld] - idoc.pub Air Compressor. 5 HP, 2-stage recommended. Filter-Regulator with gauge (#3411-12) Coalescing Filter (#3405-60) Drain Valves (Drain water daily). Elbow, steel pipe fitting.

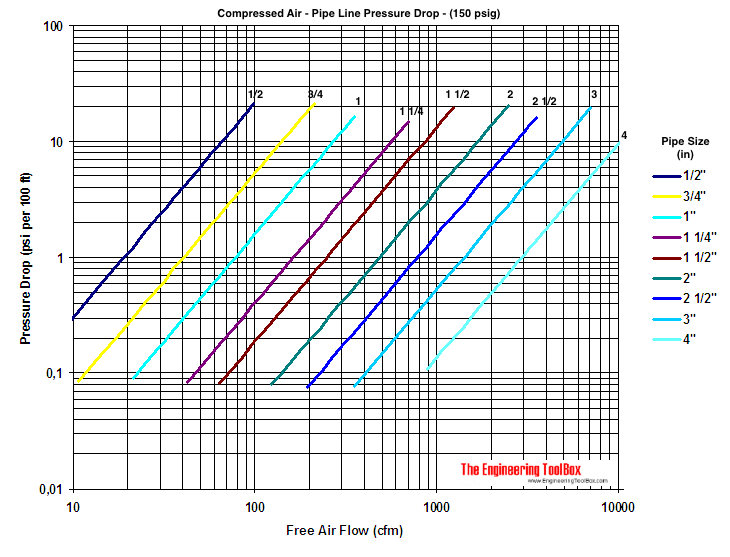

Plumbing Your Air Compressor |Powder Coating: The Complete Guide The table below shows the pressure drop through some common compressed air fittings based on CFM and pipe diameter. (ELL refers to elbows). 5. The horizontal piping running around your space should not be completely level and instead should be sloped either away from or towards your air compressor.

Air Compressor Anantomy, Breakdown Diagram, Exploded-View Drawing In the sections below you will find exploded diagrams of some of the most popular compressor parts, and how they may vary depending on the manufacturer. Piston Air Compressors A piston compressor (also known as a reciprocating compressor) uses pistons driven by a crankshaft to deliver air at high pressure.

How To Set Up An Air Compressor for Spray Guns & Painting ... The 100L air compressor kit comes complete with a HVLP gravity fed spray gun, two 6m rubber hoses with quick couplers, a spray gun filter, water trap, regulator & lubricator, euro quick couplers, mini air filter and 1 litre of AC 2068 compressor oil.

Air Piping Layout The quality of our compressed air is also effected by how our air delivery lines are laid out in our shops. The following two diagrams will show you a very good layout for shop air piping. I have also provided links so you may download these diagrams to your hard drive in Adobe PDF format where you can then print for future reference.

Piping and Ventilation Guidelines for Proper Air Compressor ... Ventilation air should be drawn from the exterior of the compressor room at the lowest and coolest possible point on one of the room's walls. On the opposite wall, temperature-controlled ventilation fans should be installed at the highest point of this wall. Cool air needs to flow across all of the equipment in the room.

Compressor Inlet Piping | Compressed Air Best Practices Support inlet piping, do not hang on the unit. Be sure pipe is free of dust, rust, weld beads, scale, chips, etc. before starting the compressor. If running over 50 feet (confirm with manufacturer), increase pipe size at least one size or greater over the filter housing connection size.

PDF METAL PIPING-The best way to install air lines and reduce moisture. - NEMES METAL PIPING-The best way to install air lines and reduce moisture. Metal Piping eliminates moisture and air volume problems Lengths of air hose can be used to connect compressor to air-operated equipment, but ONLY on a temporary basis. When using long lengths of air hose, moisture remains in a vapor form and will pass through most water ...

All You Need to Know (Diagram) | ACM - Air Compressor Machine Check out the air compressor pressure adjustment article to understand the different adjustments. Air Compressor Pressure Switch Wiring Diagram Below is the Square D pressure switch wiring diagram. Connect your power lines at 1 and 3. The motor wires would connect to 2 and 4. square d pressure switch wiring diagram FAQ (Frequently Asked Question)

Central Pneumatic Air Compressor - Fix My Compressor Mar 23, 2017 · If you have a Central Pneumatic air compressor, and you didn’t buy it used, from a garage sale, or from on on-line end-of-line wholesaler, odds are pretty good that you bought it at Harbor Freight. In 2017, Harbor Freight offers about 35 different Central Pneumatic air compressors, from a 1/6 HP air brush style to… Continue reading Central Pneumatic Air Compressor

Air Compressor Piping Diagrams And Tips | iPower Toolz Air Compressor Piping Diagrams And Tips June 18, 2022 An air compressor generates power in the form of air pressure, and for an air compressor to work efficiently it requires a certain unit. This unit is the piping , glue that holds this intricate system together. Unfortunately, setting-up seems rather easier said, than done.

Designing an Air Compressor Room Ventilation System | Kaishan USA Here are several important factors to consider in compressor room design: Select the right location for the compressor room — Situate the compressor room in as central a location as is feasible and as closely as possible to all points of use. A central location will reduce the amount of piping needed to distribute compressed air, and can ...

How to Install an Air Compressor in Your Garage | Quincy Compressor The pressure at which air is delivered from a compressor — measured in terms of psi — is another critical factor in the ability of an air compressor to power pneumatic tools properly. Certain tools demand higher psi than others, and an air compressor must exceed the maximum rating from a given set of tools to cover the owner's working needs.

How a Central Air Conditioner Works - HomeTips Jan 26, 2021 · How does an air conditioning system work? This expert article, along with diagrams and video, clearly explains how a central air conditioner cools a house by cycling refrigerant through its system and delivering chilled air through ductwork. Diagram of a central air-conditioning system of a house including a network of warm air and cold air ducts.

how does this air compressor piping diagram look | Hot Rod Forum ok well i got a 20 gallon 5hpmaxx cambell hausfeld air compressor. right now i got 3/8-in. x 50-ft. Air of hose going to a filter/dryer in my vise then 3/8-in. x 25-ft. of hose to my air tool. after a hour or 2 my air filter is full of water and needed empty, the end of the air hose still...

0 Response to "43 air compressor plumbing diagram"

Post a Comment