40 air compressor piping diagram

Air Piping Layout - Sharpe Manufacturing The quality of our compressed air is also effected by how our air delivery lines are laid out in our shops. The following two diagrams will show you a very good layout for shop air piping. I have also provided links so you may download these diagrams to your hard drive in Adobe PDF format where you can then print for future reference. Compressed Air Piping Distribution Systems | Compressed ... Instead, analysis identified that the 3" air line in bay one was experiencing a 20 psig pressure drop. Closing the loop at the far end of the bays allowed the compressors to again operate at 95-100 psig. A 20 psig lower pressure meant 10% savings: 40 KWh = $ 30,000/year. Piping cost was $ 15,000. 3.

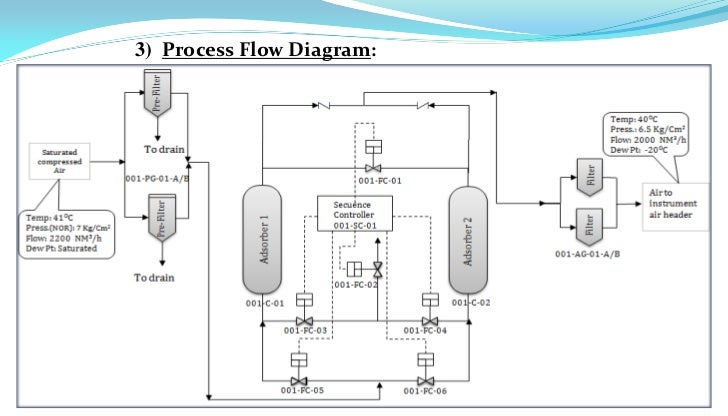

PDF Compressed Air System Standard Piping Diagram Compressed Air System Standard Piping Diagram Author: Department of Veterans Affairs, Office of Acquisition Logistics and Construction, Office of Construction and Facilities Management, Office of Facilities Planning, Facilities Standards Service Subject: Standard Detail Created Date: 10/26/2017 1:02:30 PM

Air compressor piping diagram

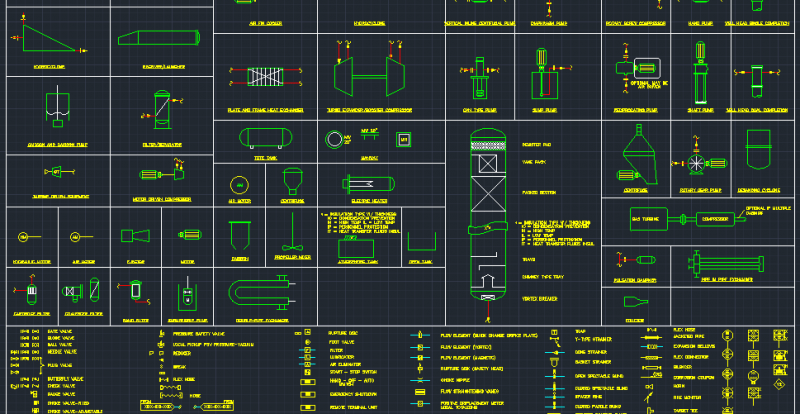

Compressed Air Basics - Piping - Air Compressor Works, Inc. We have charts and excel spreadsheets that calculate pressure drop in piping. You can also look on-line for numerous pressure drop calculators. Make sure you include the equivalent length of fittings in your calculations. Minimize the use of elbows and bends. Air Compressor Piping Diagrams And Tips Compressed Air System Piping Diagram 1. Compressed Air System Components. An air compressor is a machine used to increase the pressure and volume of air. The compressor is typically composed of a motor, a compressor wheel, and piping. The motor powers the compressor wheel, which in turn compresses the air. Air compressor piping diagrams and tips | Learn from the ... Air piping diagram angle When working on your air compressor hose diagram, you should always avoid sharp angles. This has pretty detrimental effects on piping air to the air tool. Because these sudden sharp angles slow down the flow of air, and as a result, the pressure also drops. Let me explain it with an example.

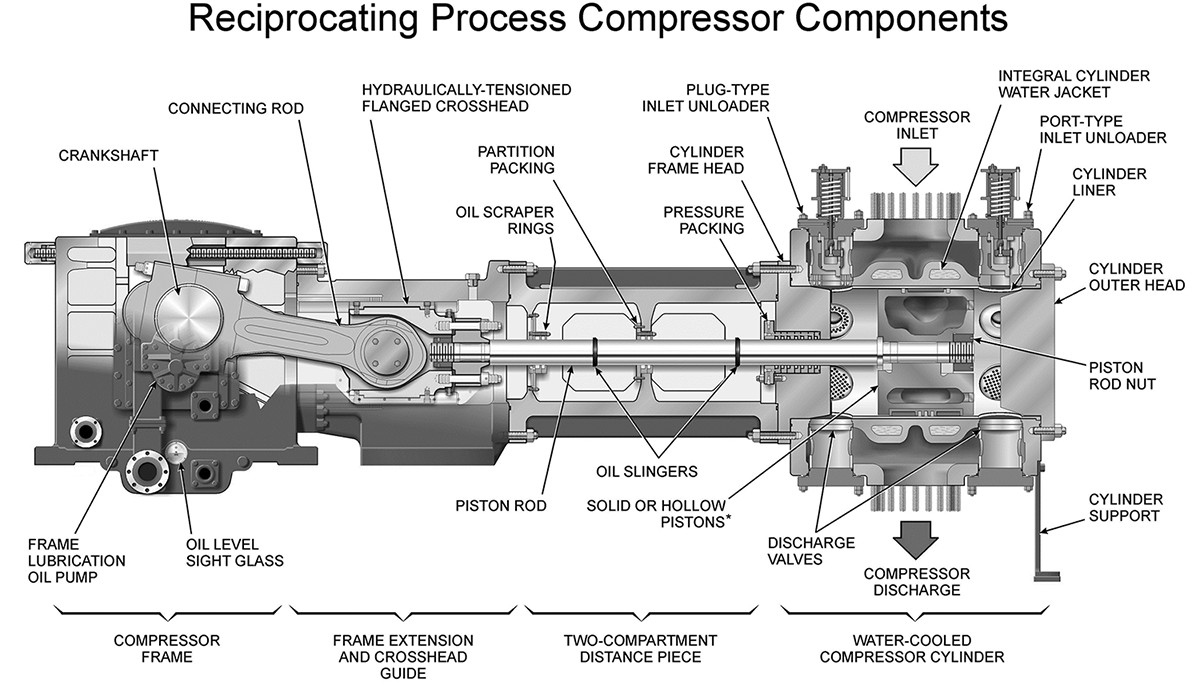

Air compressor piping diagram. Compressor Inlet Piping | Compressed Air Best Practices Install drain leg on inlet line before the air enters the compressor Discharge Piping Rotary: Pipe size should always be larger than unit connection size. Determine correct pipe size based on system flow, length of pipe, number of ends/valves, acceptable pressure drop, etc. Pipe so condensate from air line cannot run back into unit Air Compressor Anantomy, Breakdown Diagram, Exploded-View ... Air Compressor Anatomy 101. Here we we have breakdown drawings and diagrams of Piston air compressors (reciprocating aka "Recip") as well as for Rotary Screw air compressors. There are other types, but the vast majority of air compressors in use today are one of these two types. In general they consist of an air pump, a motor or engine and a ... How to Plumb an Air Compressor Setup in Garage - Ultimate ... seek a male x female valve as the outlet of the compressor is female and the outlet of the piping will be male How Sizing NPT Fittings Enhance Airflow You do not want to have air mains that are too great in size. If you have an increase in pipe size from say 3/8″ to 1″ air main then this essentially becomes a compressed air receiver. Air Compressor Piping | Quincy Compressor Pipes 20 (3/4″) - 25 (1″) - 40 (1 1/2″) - 50 (2″) - 63 (2 1/2″) - 80 (3″) - 100 (4″) - 158 (6″) MM AIRnet is Reliable, Safe, and Maintenance Free Sustainability Optimized inner body design minimizes flow resistance and pressure drop in the fittings Low friction factor and seamless connections minimize pressure drops in the pipe network

PDF Compressed Air Piping Recommendations for Compressor ... Air Compressor Discharge Piping Materials Discharge air temperatures from centrifugal, reciprocating and oil-free rotary screw air compressors can range from 250-350°F (121-177°C). Discharge air temperatures from lubricated rotary screw air compressors can range from 200-220°F (93-105°C). Even if the air compressor has SimplAir Compressed Air Piping | Ingersoll Rand PROVIDES SOLUTIONS FOR VIRTUALLY ANY NEED Simplair® piping is available in a wide range of outer diameter sizes from 3/4" to 8" (20 mm to 220 mm) to serve nearly any application. High-quality, all-metal, easy-to-install fittings make it easy for users to design and construct their own systems without the need for professional installers. Air Compressor Piping Diagrams and Tips - Tools Haunt An air compressor piping diagram is created by connecting an air compressor to any end-user tool through the use of a pipe. As simple as it may sound, creating your own piping diagram at home is rather a complicated process. Besides, you need the specific requirements of your project to come up with the correct piping. Air Compressor Piping Diagrams and Tips - Best of Machinery When there are lots of sharp angles in an air compressor piping diagram, the following happens: The speed of air slows down The flow of air is interrupted The pressure decreases Just like when you're driving, you must decrease your speed if you need to make a sharp turn. The same applies to air in an air compressor pipe system.

Guide to Compressed Air Piping Systems | Quincy Compressor Water resulting from compression comes from air drawn in by your compressor. All ambient air has a certain level of humidity. When that air is compressed, the water in it condenses from its vapor form into a liquid state. There is a simple way to reduce moisture in the piping system : change the compressor's supply inlet source. Compressed Air Piping - Pressure Loss Diagrams, Imperial Units Download and print Compressed Air - Pipe Line Pressure Drop (gauge Pressure 50 psig) Compressed air pipe line pressure loss diagrams - metric units. 1 ft (foot) = 0.3048 m. 1 cfm = 1.7 m3/h = 0.028 m3/min. 1 psi = 0.069 bar = 0.070 kg/cm2. Compressed Air Piping | Air Treatment|Gardner Denver Aluminum piping will keep your compressed air extremely clean, as it is non-corrosive. Unlike plastic pipe, aluminum can stand up over time without becoming brittle or weak. Aluminum piping is push to connect in many circumstances, making installation easy and cost effective. During the installation process, it is also best to avoid 90 degree ... PDF Distribution PiPing - Compressed Air Challenge The compressor room header into which the air compressor(s) discharge(s), should be sized so that the air velocity within the header does not exceed 20 ft/sec, thus allowing for future expansion. Distribution header piping leaving the compressor room should be sized to allow an air velocity not

Aluminum Compressed Air Piping | Air Technologies® Aluminum Compressed Air Piping We're one of the largest installers of aluminum compressed air piping systems in North America. At Air Technologies ®, we understand that your compressed air and inert gas delivery systems play a vital role in your production processes.Aluminium compressed air piping delivers air and inert gas in the most efficient and cost-effective way, which drastically ...

Air Compressor Piping Diagrams And Tips - iPower Toolz Air Compressor Piping Diagrams And Tips November 20, 2021 An air compressor generates power in the form of air pressure, and for an air compressor to work efficiently it requires a certain unit. This unit is the piping , glue that holds this intricate system together. Unfortunately, setting-up seems rather easier said, than done.

Plumb your shop for air | Wood - WOOD Magazine Connecting an air compressor to the pipe system with a short, flexible hose lets you disconnect it should you need to take the compressor elsewhere. This hose also isolates compressor vibration, blocking it from transferring into the pipe network. A pass-through filter near the compressor traps most contaminants and water to keep the lines clean.

PDF METAL PIPING-The best way to install air lines and reduce ... METAL PIPING-The best way to install air lines and reduce moisture. Metal Piping eliminates moisture and air volume problems Lengths of air hose can be used to connect compressor to air-operated equipment, but ONLY on a temporary basis. When using long lengths of air hose, moisture remains in a vapor form and will pass through most water ...

Water Cooled Reciprocating Bitzer Compressor Brine Chiller With -45C Outlet Manufacturers China ...

Air Compressor Piping Diagrams and Tips - Home Tool Guides Top Tips for your Air Compressor Piping Diagrams Be sure to use a pipe cutter to cut steel pipes and a hacksaw for plastic pipes. The cut edges of steel pipes are very sharp. You can hold them in a small vice and cut the pipes with a pair of wire cutters. Insulate your piping to avoid condensation. Use pipe insulation or foam pipe wrap.

Air Compressor Piping Diagrams and Tips From Experts ... It's important to reduce the number of elbows/sharp angles in your piping diagram. They reduce the speed of airflow and therefore cause pressure drop. The most efficient pathway is a straight one. This avoids energy being wasted as air ricochets around the pipe after a sharp angle. Regulating Moisture Levels

PDF How to know what size piping your Compressed Air System needs Remember that an oversize pipe compensates for possible scale build-up and provides for future expansion of the overall air system. Steps to figuring what size piping your compressed air system needs: 1. Determine your air compressor's maximum CFM. 2. Draw a piping schematic and show all pipe fittings, valves, etc. 3.

how does this air compressor piping diagram look | Hot Rod ... Weld the ends, on the side at one end, weld a 3/8 pipe nipple, on the other end, 180 degrees from the first nipple weld another. Then drill through the nipples with a 5/16 drill. Hook the inlet air to the bottom, and outlet to the top. Sorry, you'll need and 1/4 nipple on the end which will be the bottom to drain it.

0 Response to "40 air compressor piping diagram"

Post a Comment