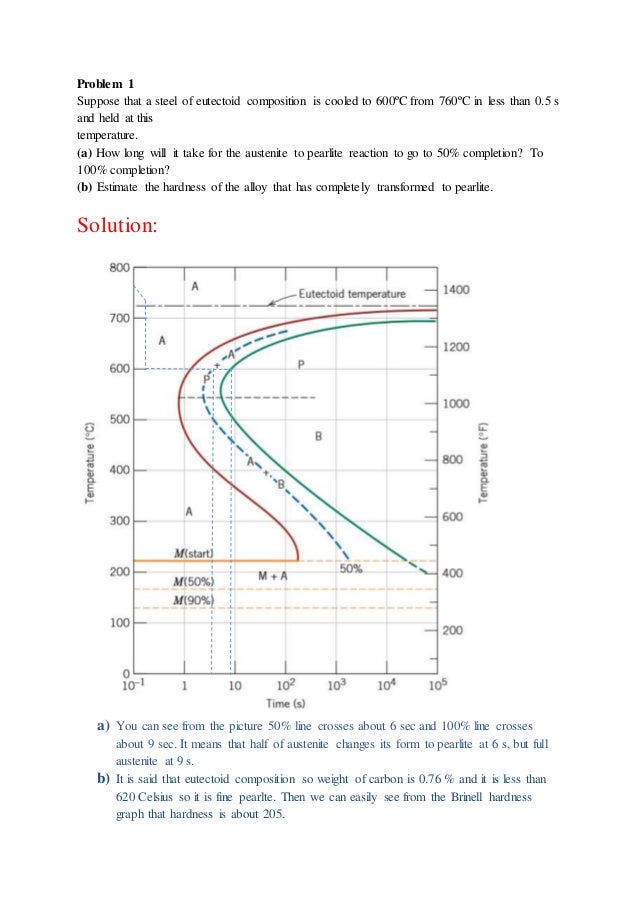

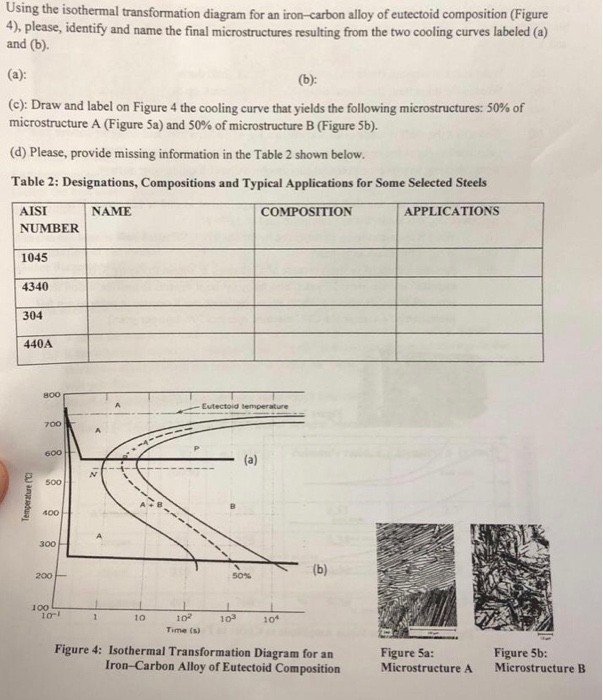

41 using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition

Answered: Using the isothermal transformation… | bartleby Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition, specify the nature of the final composition in terms of microconstituents present and approximate percentages: a) Rapidly cool to 350 oC, hold for 104 s, and quench to room temperature. Solved 7.3. Using the isothermal transformation diagram for - Chegg (a) Cool rapidly to 350°, hold for 103 s, then quench to room temperature. (b) Rapidly cool to 625°C, hold for 10 s, then quench to room temperature. (c) Rapidly cool to 600°C, hold for 4 s, rapidly cool to 450°C , hold for 10 s, then quench to room temperature. (d) Reheat the specimen in part (c) to 700°C for 20 h.

Make a copy of the isothermal transformation diagram for an iron-carbon ... Make a copy of the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 11.14) and then sketch and label on this diagram time- temperature paths to produce the following microstructures: (a) 100% coarse pearlite. (b) 100% tempered martensite. (c) 50% coarse pearlite, 25% bainite, and 25% martensite.

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition

Iron-Carbon Phase Diagram Explained [with Graphs] - Fractory The weight percentage scale on the X-axis of the iron carbon phase diagram goes from 0% up to 6.67% Carbon. Up to a maximum carbon content of 0.008% weight of Carbon, the metal is simply called iron or pure iron. It exists in the α-ferrite form at room temperature. From 0.008% up to 2.14% carbon content, the iron carbon alloy is called steel. Problem 3 Using the isothermal transformation diagram for an iron ... Problem 3: Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (given below), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. Chapter 11 / Phase Transformations - SLIDEBLAST.COM EXAMPLE PROBLEM 11.1 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 11.14), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages) of a small specimen that has been subjected to the following time-temperature treatments.

Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition. Using the isothermal transformation diagram for an iron-carbon alloy of Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of micro constituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume ... PDF CHAPTERS 9 & 10 PHASE DIAGRAMS and TRANSFORMATIONS IN METALS SOLUTIONS ... We are called upon to consider the isothermal transformation of an iron- carbon alloy of eutectoid composition. Refer to the complete T-T-T diagram for steel of the eutectoid composition (0.76 wt. % ... 10.18 Below is shown an isothermal transformation diagram for a 0.45 wt% C iron-carbon alloy, with time-temperature paths that will produce (a ... Solved Using the isothermal transformation diagram for an - Chegg Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (see Figure 10.22 below), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following temperature treatments. PDF Isothermal Transformation Diagrams - University of Portland 10.18 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

Using the isothermal transformation diagram for an iron-carbon alloy of ... Textbook solution for Materials Science and Engineering: An Introduction -… 9th Edition Callister Chapter 10.9 Problem 19QP. We have step-by-step solutions for your textbooks written by Bartleby experts! PDF Time-Temperature-Transformation (TTT) Curves - University of Babylon It is also called isothermal transformation diagram Pearlite The eutectoid reaction is fundamental to the development of microstructures in steel alloys. (0.76 wt% C) ⇌ (0.022 wt% C) + Fe 3 C (6.70 wt% C) -Pearlite is the microstructural product of this transformation. ET 2300 HW #11 Flashcards - Quizlet Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition, specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In each case assume that the specimen ... Homework 9 - HOMEWORK 9 1. Using the isothermal transformation diagram ... Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition, specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of eac h) of a small specimen that has been subjected to

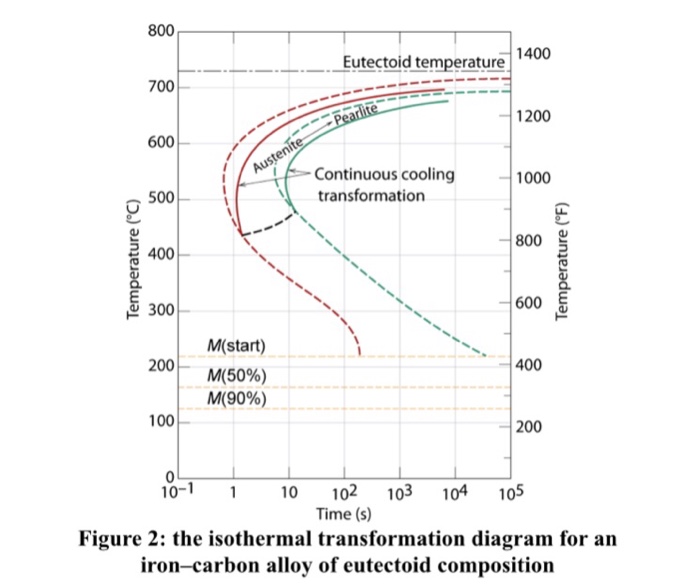

TTT diagram for steel, eutectoid steel - Learn Mechanical Engineering T-T-T diagram is also called isothermal transformation diagram [Temperature-Time -Transformation]. It is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. It is used to determine when transformations begin and end for an isothermal [constant thermal] heat treatment of a previously austenitized alloy. Using the isothermal transformation diagram for an iron-carbon a Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure), specify the nature of the final microstructure (in terms of micro constituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. PDF TTT & CCT Diagram Part 2 Lect-6 - University of Technology, Iraq Using the isothermal transformation diagram for an iron—carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstmcture (in tenns of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time—temperature treatments. (Solved) - Using the isothermal transformation diagram for an iron ... Using the isothermal transformation ...

1019 Using the isothermal transformation diagram for an iron carbon ... 10.19 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

Assignment 2 solutions - SlideShare Problem 2 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time- temperature treatments.

SOLVED:Using the isothermal transformation diagram for an iron-carbon ... Problem 19 Easy Difficulty. Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure $10.22$ ), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

TTT Curves 1 | PDF | Heat Treating | Steel - Scribd cementite layers in pearlite is approximately Figure 10.14 Isothermal transformation diagram for a eutectoid iron- 8 to 1. carbon alloy, with superimposed isothermal heat treatment curve (ABCD). Microstructures before, during, and after the austenite-to pearlite transformation are shown. f The thickness ratio of the ferrite and cementite

Using the isothermal transformation diagram for an iron-carbon alloy of ... Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of micro-constituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

PDF Time Temperature Transformation (TTT) Diagrams - University of Cambridge Fig. 4 shows the schematic TTT diagram for eutectoid plain carbon steel 8. Fig.4: Time temperature transformation (schematic) diagram for plain carbon ... Nature of transformation-isothermal or athermal (time independent) or mixed ... Equiaxed ferrite forms at lower carbon composition less than 0.29 wt%C. 25. Weight % carbon e A e3 0.0218 0.77 ...

Using the isothermal transformation diagram for an iron-carb - Quizlet Question Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition, specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

SOLVED:Using the isothermal transformation diagram for an iron-carbon ... Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22 ), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments.

0 Response to "41 using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition"

Post a Comment