42 ethane cracker process flow diagram

Free Online Process Flow Diagram Maker | EdrawMax Online A process flow diagram is a graphical way of illustrating a process and the tasks in sequential order. EdrawMax Online offers features that ease down your efforts in creating process flow diagrams, like abundant resources and symbols, massive built-in template, professional themes, intuitive interface, and more. Get Inspired from Template Community Understanding Naphtha and Ethane Cracking Processes - Hose Master The majority of ethylene is produced using a process called "steam cracking", a thermal process where hydrocarbons are broken down, or "cracked" into smaller molecules that are then used to manufacture more useful (and valuable) chemicals. In the petrochemical industry, two of the main feedstocks for steam crackers are naphtha and ethane.

Process flow diagram for ethane crackers (areas in red are not needed ... Process flow diagram for ethane crackers (areas in red are not needed in ethane plants) Source publication Techno-Economic Analysis of Oxidative Dehydrogenation Options Article Full-text available...

Ethane cracker process flow diagram

Ethane Cracker Plants: What Are They? - Climate Reality Project Ethane crackers are plants that perform the first step in the process of transforming ethane - a component of natural gas - into plastics products. First, the plants separate ethane from natural gas to produce ethylene, the building block of plastics and other industrial products. The plants use extreme heat to "crack" the molecular ... Design and Optimization of Ethylene Plant: Cracking Furnace, Cracked ... The objective of our capstone project was to design and optimize the reactor, cracked gas compressor, and demethanizer distillation column of a small-scale Ethylene plant (100,000 t/y); while accounting for process safety through process control loops, environmental regulations, and economic considerations to determine the feasibility of the plant. Ethane to Ethylene (G1) - processdesign Natural gas combustion within the furnace raises temperatures high enough to induce the cracking reaction that converts ethane to ethylene. The cracked gas effluent is rapidly quenched with heavy oil and water before being mixed with the sweet shale gas. These operations were simulated in Aspen HYSYS v8.0.

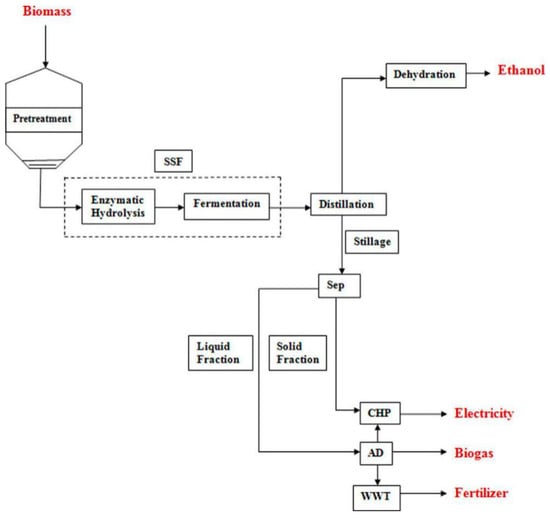

Ethane cracker process flow diagram. Ethane Cracker Process flow diagram The process depicted in the Ethane Cracker Process Flow Diagram is a steam-cracking process for producing ethylene from an ethane-propane mixture. Cracking and quenching, compression and drying, and separation are the three main stages of the process. PDF Technoeconomic Analysis on an Electrochemical Nonoxidative ... Ethylene production via the current industry-standard process of steam cracking, for example, is energy intensive and uses large furnaces burning large amounts of natural gas to "crack" feedstocks from ethane and naphtha to heavy gasoils into lighter olefinic molecules (such as ethylene, propylene, etc). PDF Naphtha Cracker Process Flow Diagram april 26th, 2018 - improving ethylene plant cracking furnace performance with process gas chromatographs application note chemical figure 1 flow diagram of a typical cracking furnace in' 'Steam Cracking Kinetics and 21 / 91 Improvement in Transient Operation of Ethane Cracker - AIChE step was to collect process information. It included process flow diagrams (PFD), piping & instrumentation diagrams (P&ID), equipment and instrumentation specifications, operation philosophy, standard operating procedures (SOP) - startup, shut down, normal and transient, process safety studies like process

Steam Cracking Process - Petrochemical Processes - Beyond Discovery Block diagram for producing ethylene from ethane. An olefin plant that uses liquid feeds requires an additional pyrolysis furnace, an effluent quench exchanger, and a primary fractionator for fuel oil separation. Process Variables The important process variables are reactor temperature, residence time, and steam/hydrocarbon ratio. PPTX Economical advantage - AIChE Economical advantage Advances in Ethane Cracking Gabriel Castaneda, P.E. Gabchem Solutions Linde (713) 873 1708 Gabriel@gabcheminc.com Table of Contents Economics Process Overview Areas of Improvement Energy Consumption Reliability / Operational Issues Compression and Fouling Refrigeration Furnaces Economical Advantage Mark Eramo, IHS PDF Appendix A Permit Application Summary - West Virginia Department of ... A process flow diagram for the Ethane Cracker Plant is presented in Figure 2-1, which outlines all major processes and equipment, including cracking furnaces, a quench tower, a compressor section, a caustic removal section, an ethylene recovery section, and the thermal oxidizer. PDF Ethylene Production - Emerson The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace. This process is called pyrolysis. Pyrolysis is the thermal cracking of petroleum hydrocarbons with steam, also called steam cracking.

Shale Gas to Ethylene (G2) - processdesign The proposed design consists of six main sections: acid gas removal, dehydration, fractionation train, hydrogenation reactor, an ethylene splitter and steam cracking (refer to Appendix B for the process flow diagram). Carbon dioxide must first be removed from the inlet shale gas in the acid gas removal section. PDF Ethylene Production Plant Design - Joshua Mayourian For each iteration, the acetylene was hydrogenated, and then 100% of the ethane was recycled. This was repeated until the recycled ethane was extinct. These iterations were performed on Table 2.2: Furnace Product Stream Composition Component Mass Flow Rate (lb/hr) Mass Percent in Stream H 2 CH 4 C 2H 2 844 0.6 C 2H 4 C 2H 6 C 3H 4 C 3H 6 C 3H 8 ... Ethylene Production via Cracking of Ethane-Propane This process diagram shows an ethylene-production process via the cracking of an ethane-propane mixture Cracking and quenching. Initially, an ethane-propane mixture is fed to furnaces in which, under high-severity conditions, it is cracked, forming ethylene, propylene and other byproducts. Ethylene Plant - an overview | ScienceDirect Topics Ethylene plants, also sometimes referred to as steam crackers, consist of five main sections. These are as follows: • furnace section • quench section • cracked gas compression • recovery and purification • refrigeration The furnace section is where the feed is converted to ethylene, propylene, and coproducts.

PDF THE U.S. ENVIRONMENTAL PROTECTION AGENCY - Archives | US EPA Update #8 Updated Process Flow Diagram Appendix B -Process Flow Diagrams Update #9 Use of high hydrogen fuel Appendix C-GHG Emissions ... The ethane is fed to five cracking furnaces to heat the ethane to cracking temperature. To reduce coke formation in the cracking furnace tubes, a sulfide material is added continuously

PDF Appendix C Process Flow Diagrams Appendix C Process Flow Diagrams Acid Gas Removal Chilling Train Once Furnace Hot Stand-by/Decoking Five Furnaces Normal Operations Quench Tower Natural Gas Feeds Recycle Feeds Oxidizer Feeds Product Feeds Fuel Burning Equipment Thermal Oxidizer Figure C -1: Ethane Cracker Process Flow Diagram C2 Cut C2 Splitter Ethylene Storage

Oxidative dehydrogenation of ethane under a cyclic redox scheme ... The energy demand for ODH decreases with increasing single-pass ethane conversion. 2. Process descriptions Fig. 1 a is a simplified process flow diagram of a state-of-the-art ethane steam cracking process. Pre-heated ethane is thermally cracked in the presence of steam, which functions as a diluent for higher conversions and as a coke-retardant.

What is the thermal cracking of ethane? - Vivu.tv An ethane cracker takes ethane, a component of natural gas found in abundance in the Marcellus shale, and process, or 'crack' it into ethylene. It does this by heating the ethane up so hot that it breaks apart the molecular bonds holding it together to form ethylene. What is the pressure maintained during the process of thermal cracking?

(PDF) Simulation and Analysis of Ethane Cracking Process using ethane as a fe edstock is simul ated for the molecular reaction scheme with 8 components and 5 reactions. A detailed free-radical mechanism for the reaction kinetics coupled with material,...

0 Response to "42 ethane cracker process flow diagram"

Post a Comment