40 blow off valve diagram

Internal wastegate, actuator, blow off valve EXPLAINED So, this is the chain of command for boost control: [manual boost controller or electronic boost controller]-> [actuator]-> [internal wastegate] Now, let's move on to the blow off valve (BOV). BOV is not directly related to boost as long as it functions properly. Product Fitting Instructions • Turbosmart Spring Combination Chart - Gen 4 WG50 & WG60 Range (6 bolt) Spring Combination Chart - Gen 4 High-Pressure Wastegates & IWG-75 HP Range (Locking Collar) Fitting Guides Blow Off Valves Current Blow off Valves - Universal Fit Dual Port - Universal Plumb Black - Universal GenV Race Port - Universal GenV Race Port HE Sensor Cap - Universal

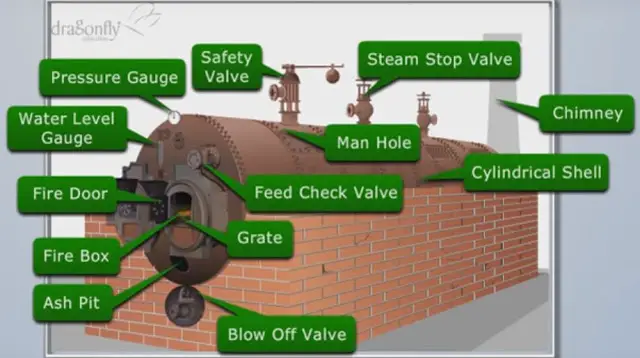

PDF Your guide to safer boiler operation 3. Water column blow-down valve 4. Pressuretrols (one is high-limit safety) 5. Steam pressure-gauge 6. Water column clean-out (cross tee) 7. Bottom blow-off and drain valve 8. Low-water cutoff/blow-off valve Note: Second low-water-cutoff not shown in diagram. Hot-water boiler. A. Expansion tank B. Low-water cutoff C. Combination temperature ...

Blow off valve diagram

Blow-off Valve | Industrial Controls Yarway blow-off valves are designed in conformance with all code requirements (ASME Section l, ANSI B31.1, ANSI B16.34). Because the primary purpose of a blowoff valve is removal of dirt, sediment and scale, the boiler code requires that valves which have dams or pockets in which sediment can accumulate cannot be used in blow-off service. This ... PDF Manual Blow-Off Valves - Emerson YarwaY hardseat and seatless tandem blow-off valve service and operation manual how to operate and service hardseat and seatless unit tandem blow-off valves the hardseat inlet valve is mounted in a one piece forget steel block body with the seatless discharge valve. the valve has a cone seat and disc design with a metal-to metal seat. the How does a Blow Off Valve work? - Nuke Performance What is the purpose of a Blow Off Valve? A blow off valve is actually a Pressure release valve that releases turbo pressure / boost when the throttle plate is closed. While the turbo is still spinning and creating pressure, a wave of pressure will travel back to the turbocharger when the throttle close, this will results in that the compressor ...

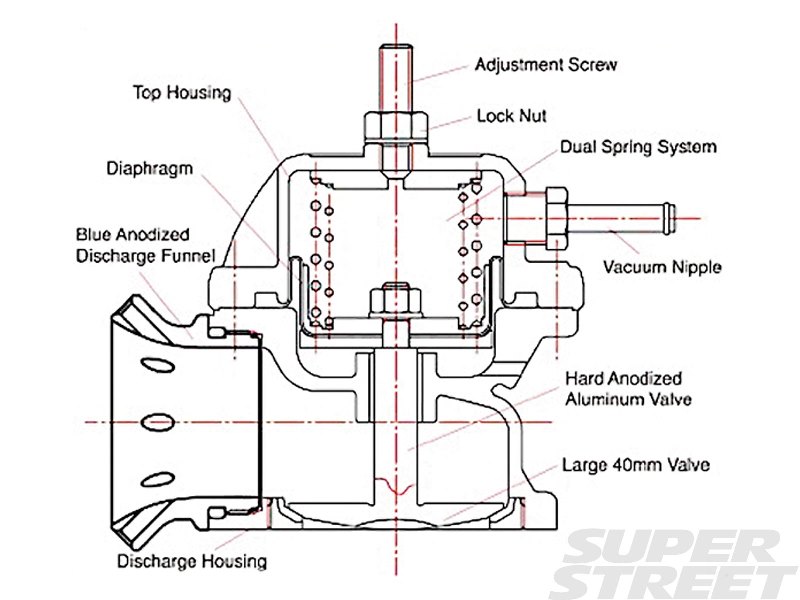

Blow off valve diagram. Bypass Valve | Installation Manuals | Vortech Superchargers Want to know how to install a Mondo Bypass Valve or Maxflow Bypass Valve? Click here see all you need to know! Boost your Performance with Vortech Superchargers. Dropdown trigger. My Account. My Wishlist. Search. Order online or call us (805) 247 0226. ISO 9001:2008+ AS9100C CERTIFIED PDF Synchronic Blow-Off Valve TUNING MANUAL Synchronic Blow-Off Valve TUNING MANUAL 2 INDEX I.SB001Diagram II. Installing and Removing the Recirculation Fitting III. Installing and Removing Mounting Flanges IV. Filtering the Inlet V. Connecting to a Vacuum Source VI. Recirculating the Discharge VII. Adjusting for Response VIII. Anti-Stall Valve Kit IX. Mounting Flange Options Power Adder Tech: Properly Sizing Blowoff Valves And Wastegates Blowoff Valves: How They Work Picture how a turbocharger system works here, as our first example. There's a turbine side and a compressor side. The turbine side is driven by the exhaust gases from the engine, spinning the compressor side, sending a charge of compressed air to the engine. The distance this air discharge travels can vary. PDF YARWAY BLOW-OFF VALVES SEATLESS, HARDSEAT AND UNIT TANDEM - Emerson The seatless blow-off valve is a sliding plunger type, opened and closed by means of a handwheel and non-rising stem, and sealed against leakage by packing rings above and below the ports. This valve is provided with heavy coil compression springs under the yoke nuts.

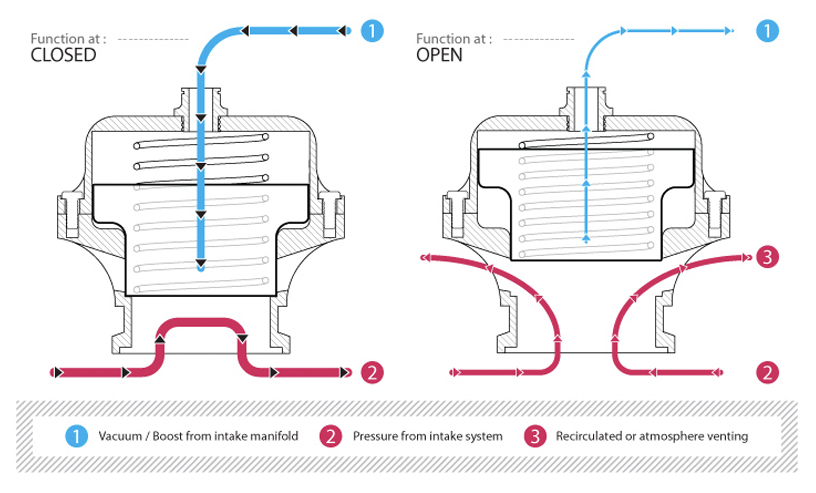

!!!Must See!!! How To Run Wastegate & Blow Off Valve Vacuum Lines HOW TO RUN VACUUM LINES FOR WASTEGATE & BLOW OFF VALVEPayPal Donate ... DDG- Blow off valves explained - The Dodge Garage A blow off valve or shift valve is a device that allows boost pressure to be relieved from the intercooler hoses when shifting and the throttle blade is closed. This has two benefits: ... The first diagram is useful for anybody running a stock or Bosch BOV, or any BOV made of plastic. If you leave the factory's quick release valve in place, the ... What are blow off valves and can I put them on my N/A car? Air is released. Pardon the noobness of the diagram! This is why blow off valves exist. It releases turbocharged air coming down the wrong direction of the intake manifold out to the atmosphere.... How Does a Blow Off Valve Work? - The BUILD by Torqued Distribution There are two different blow off valves; re-circulating and vented/atmospheric blow off valves. A re-circulated BOV is one where the boost pressure is re-circulated back into the intake, in order not to affect the engine already measured air/fuel mix. A vented BOV is one where the air is released out to the atmosphere instead of being reused.

Boiler Mountings - Functions, Parts, Diagram, Working High stem low ware safety valve diagram When the water level falls and floats are sufficiently uncovered from water, the weight of the float increases and no longer. It is balanced by the balance weights. Consequently, the float end of the lever will descend and causes a swing in the lever A. When the lever swings, the valve rod is pushed up. Quick Tech: Wastegates vs. Blow-Off Valves...What's the Difference ... What is a Blow-Off Valve? A blow-off valve (BOV) is similar to a wastegate, but works on the intake side of the turbocharger. The BOV prevents pressure from building up in the intake tract. Excess pressure in the intake (ahead of the turbo) can back up and then cause compressor surge when the engine speed changes suddenly. Tial Q Blow Off Valve - Boost Lab, Inc This Blow Off Valve features a large, 1.98 in (50.5mm) valve. The valve seal utilizes a high pressure Viton O-Ring that is clamped in place to prevent the possibility of sticking to the seat and pulling out. The valve stem and guide are Teflon-lubricated and hard anodize-coated for wear resistance. Blow Off Valve Install: - TwinTurbo.NET: Nissan 300ZX forum Start assembling the BOVs. First attach the small hose (green dots in 3.) between the two fittings on the BOV. Remember to put the hose clamps on the tube before pushing them on the fittings. Put a little WD40 on the fitting, it makes it MUCH easier to put the rubber hose on. Bolt the chrome tube to the BOV ( 4.

Blow Off Valve Diagram - Ozhonda.com Why do you need a Blow-off Valve (BOV)? To eliminate compressor surge when changing gears. Excessive backpressure is created when the throttle is closed during gear changes or deceleration, causing turbo cavitation. This is detrimental to the life of your turbocharger; however fitting a BOV will substantially improve this problem.

Blow Off Valves 101: Function, Horsepower, Tuning & Warranty A blow off valve releases the high pressure trapped in the engine's intake into the atmosphere or recirculating the pressure back to the turbo intake. This works as an anti-compression surge device in the turbocharged system. To understand "what blow-off valves do and how exactly it works".

How to install a Blow off/ Dump valve - YouTube Welcome Bluudies, In this Video I fit a Blow off valve (BOV) AKA a Dump Valve to the 2.0 Turbo Engine in the astra. This same method will apply to many diffe...

Centrifugal Air Compressor Controls and Sizing Basics Check valve; Control panel; Figure 2. This diagram maps the basic internal processes of a centrifugal air compressor. ... In reality, it hits an offset from the surge line, and sometimes pressure is allowed to rise and control the blow-off valve with the IGV at min position. In other controllers, both valves are stroked simultaneously as the ...

Blowoff valve - Wikipedia Throttle closed, air pushes the blowoff valve open (upwards) A blowoff valve (also called dump valve or compressor bypass valve) is a pressure release system present in most petrol turbocharged engines. Blowoff valves are used to reduce pressure in the intake system as the throttle is closed, thus preventing compressor surge. [1] Contents 1 Design

Installation diagram for Bv50 BoV - TiAL Racing Blow-off Valves ... Installation instructions for TiAL BV50 displaying intake throttle plate, Vacuum Signal (lines 6mm I.D.), Blow off Valve and Compressor Discharge . For sale to distributors, from Spain's official distributor turboMaster

All you ever needed to know about blow-off valves The pressure on the bottom of the valve and the vacuum on the top combine to lift the valve open and release the pressure in the turbo piping, since it can no longer go into the engine. Blow-off valve myth #1: One of the biggest misconceptions about blow-off valves is that you need to tighten the spring to run higher boost.

The Difference Between Wastegates and Blow-Off Valves When a BOV is vented to atmosphere, it produces a distinctive hissing sound, and when a BOV isn't used or is of insufficient size, the compressor surges and makes a chirping or rattling sound ...

Blow Off Valve BOV basics | diverter bypass valve | Vented Vs Returned A blow off valve is an important part to any turbocharged or supercharged vehicle. These valves save our forced induction components in a way that most users may over look. Other terms you may hear or read about that are essentially the same thing to Blow Off Valve, are recirc valves, diverter valve, bypass valves, or the abbreviation BOV.

Boiler Blowdown Valve Sequence Explained - Everlasting Valve Company Everlasting Valves offers manual on-off valves designed to effectively blowdown sludge, in quick opening and slow opening straight and angle configurations. Our valves are ideal for applications including steam boiler blowdown, surface blowdown, water column drain, and shut-off and stop valves.

How does a Blow Off Valve work? - Nuke Performance What is the purpose of a Blow Off Valve? A blow off valve is actually a Pressure release valve that releases turbo pressure / boost when the throttle plate is closed. While the turbo is still spinning and creating pressure, a wave of pressure will travel back to the turbocharger when the throttle close, this will results in that the compressor ...

PDF Manual Blow-Off Valves - Emerson YarwaY hardseat and seatless tandem blow-off valve service and operation manual how to operate and service hardseat and seatless unit tandem blow-off valves the hardseat inlet valve is mounted in a one piece forget steel block body with the seatless discharge valve. the valve has a cone seat and disc design with a metal-to metal seat. the

Blow-off Valve | Industrial Controls Yarway blow-off valves are designed in conformance with all code requirements (ASME Section l, ANSI B31.1, ANSI B16.34). Because the primary purpose of a blowoff valve is removal of dirt, sediment and scale, the boiler code requires that valves which have dams or pockets in which sediment can accumulate cannot be used in blow-off service. This ...

0 Response to "40 blow off valve diagram"

Post a Comment