39 iron iron carbide phase diagram

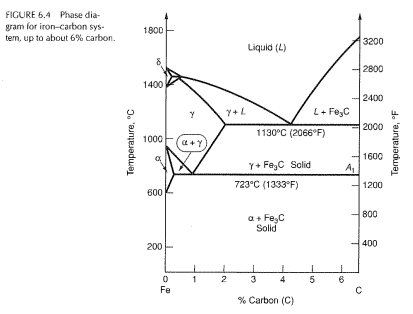

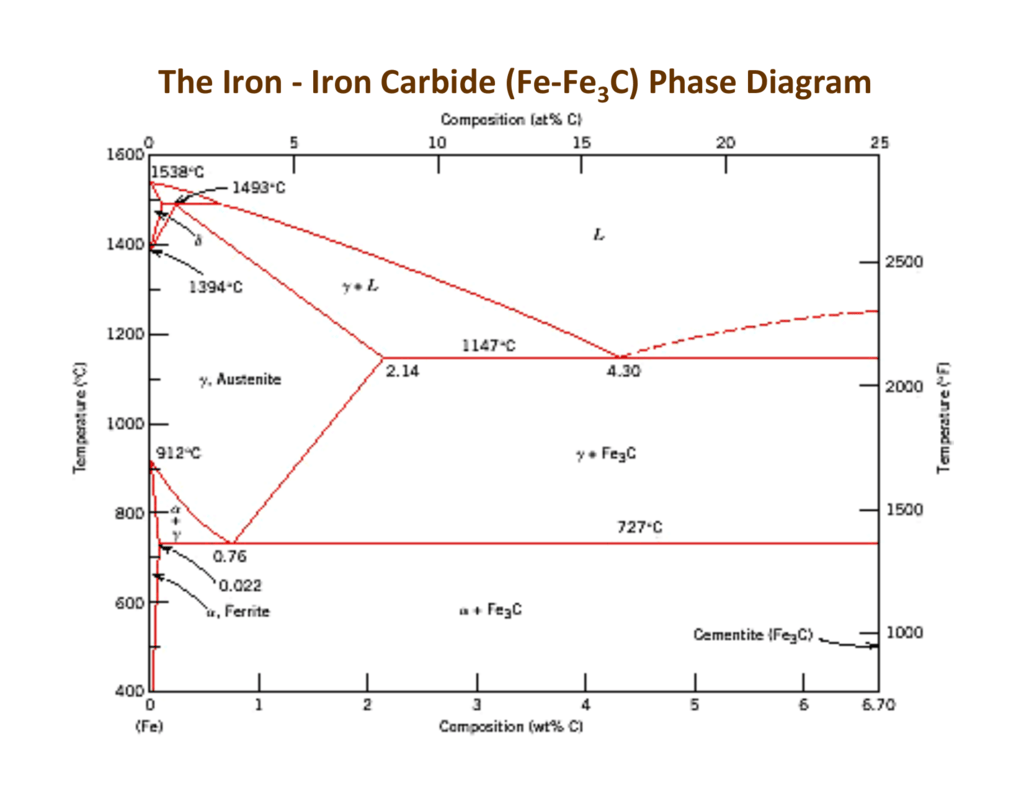

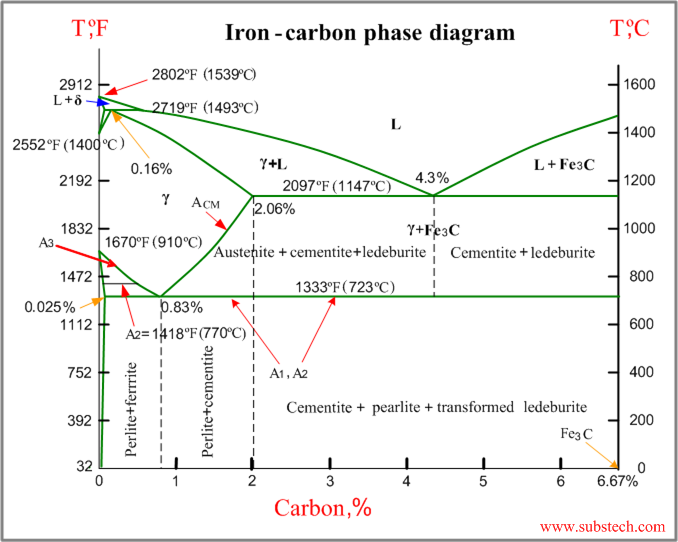

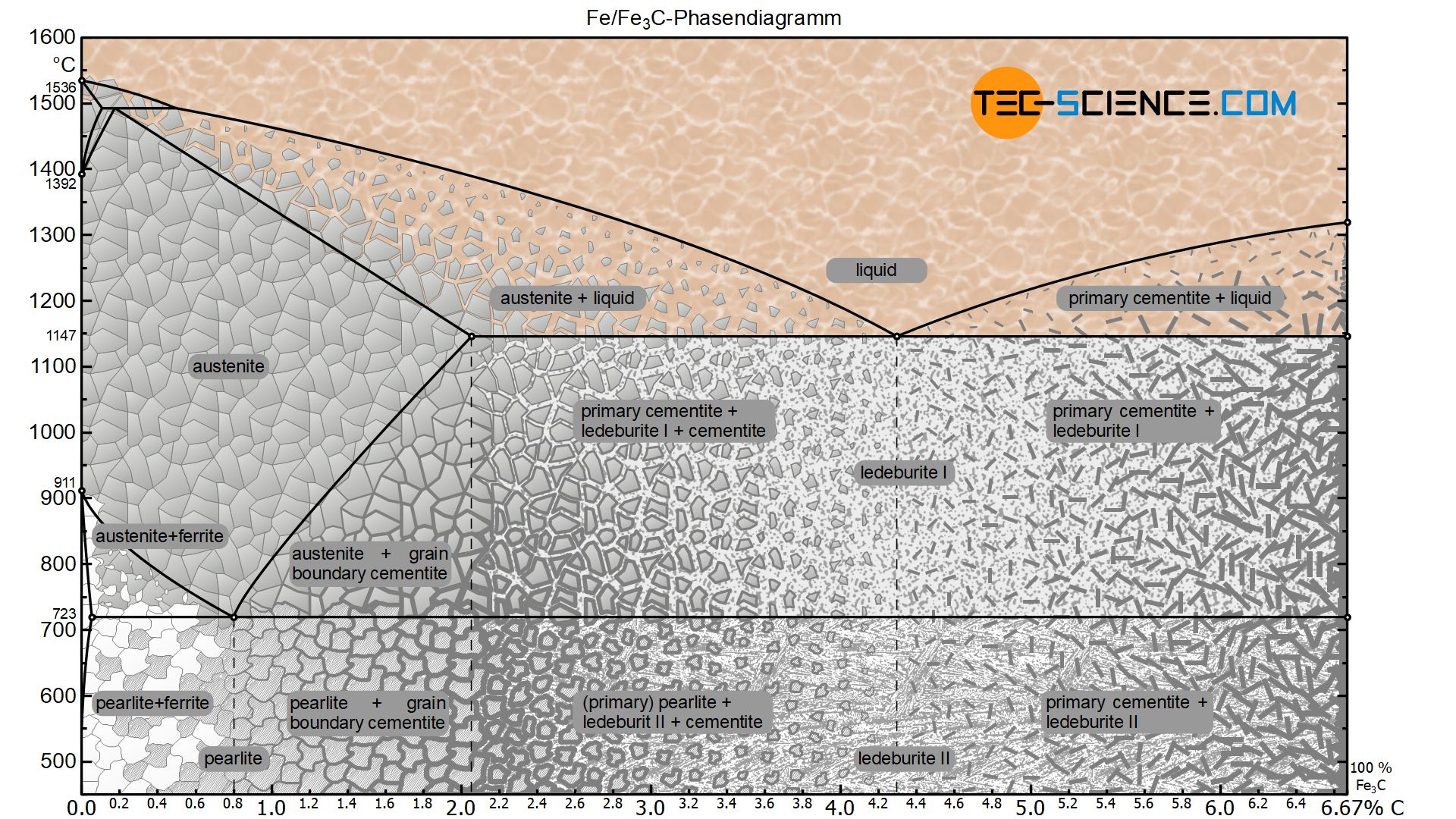

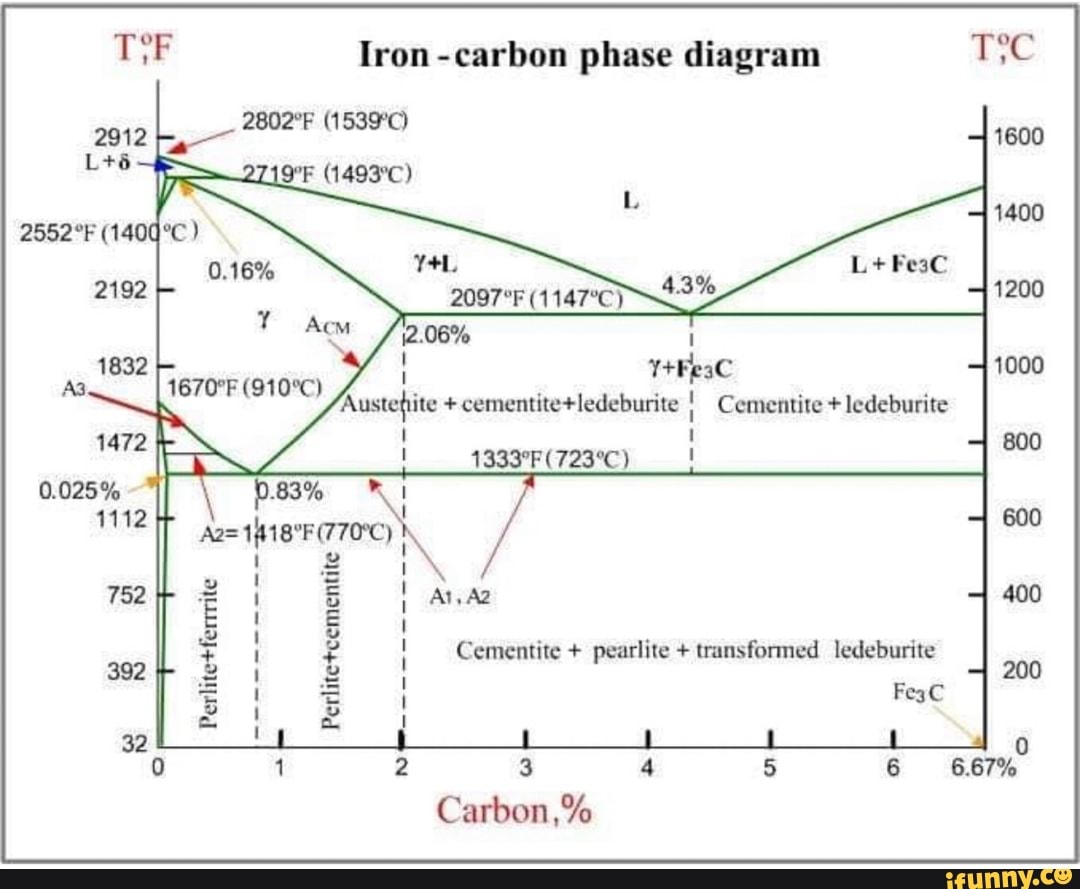

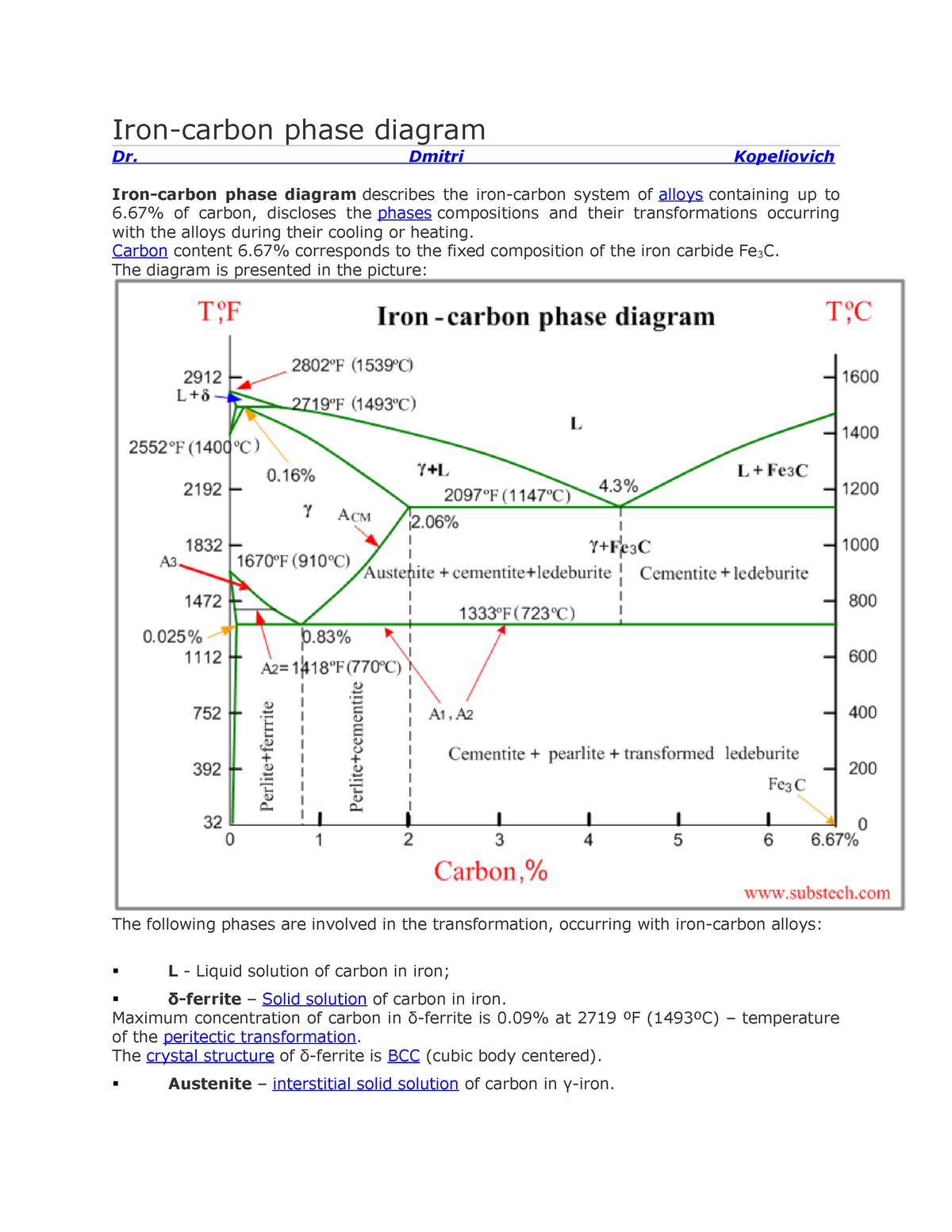

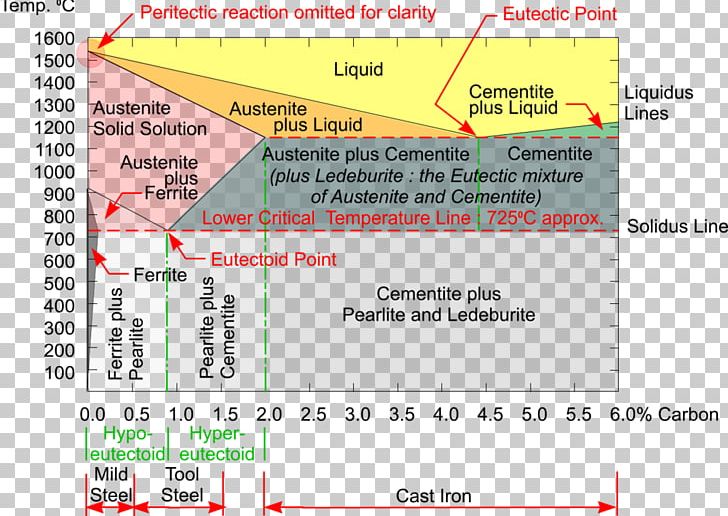

Hi everyone in this video I will show you how to read or how to use iron iron carbide equilibrium diagram in metallurgical and materials systems.#iron_iron_c... The Iron-Iron Carbide Diagram. The part of iron-carbon alloy system diagram between pure iron and an interstitial compound, iron carbide (Fe 3 C), containing 6.67 percent carbon by weight is called iron-iron carbide equilibrium diagram. It may be noted that though it is called as equilibrium diagram, it is not a true equilibrium diagram, since ...

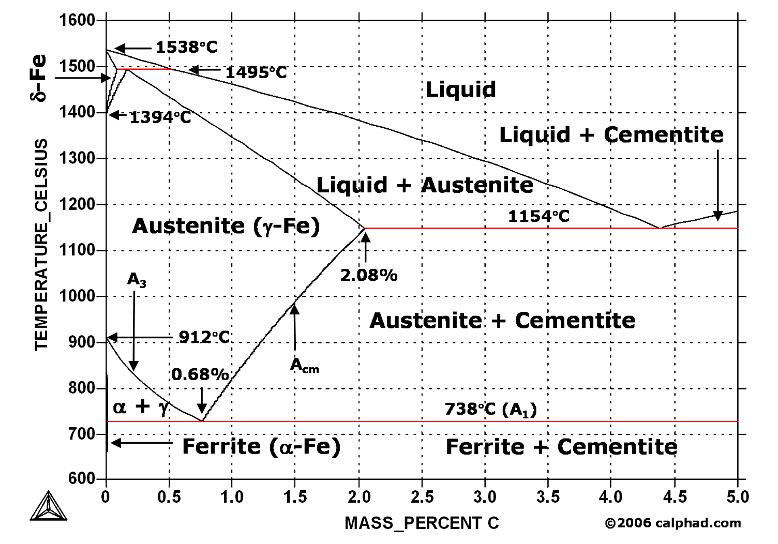

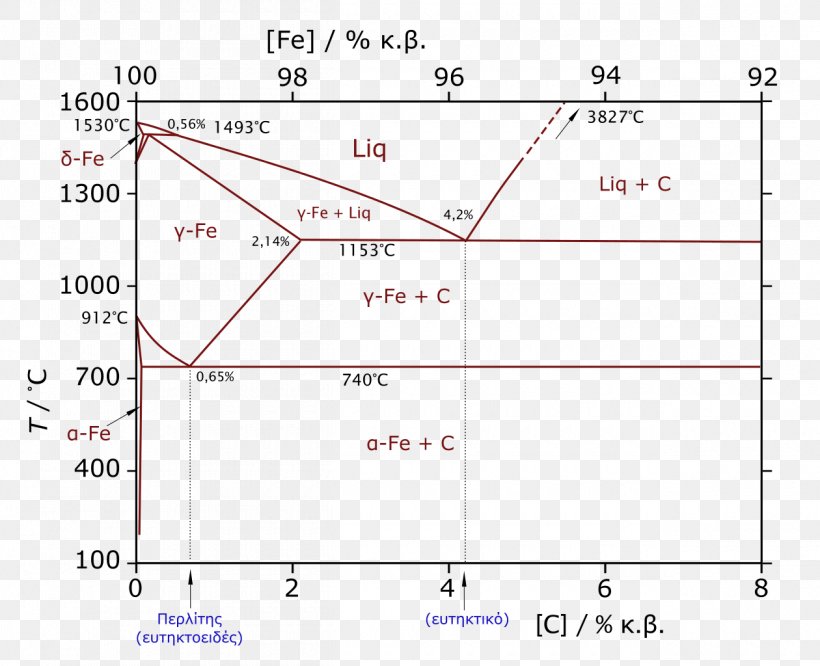

C Phase Diagram ¾α‐ferrite‐solid solution of C in BCC Fe •Stable form of iron at room temperature. • Transforms to FCC g‐austenite at 912 °C ¾γ‐austenite‐solid solution of C in FCC Fe • Transforms to BCC δ‐ferrite at 1395 °C •Is not stable below the eutectic temperature (727 °C)

Iron iron carbide phase diagram

Oct 21, 2021 · Fig. 12 shows the phase constitutions of two HCCIs with and without Ti during cooling. In the liquid phase containing Ti and C, the TiC phase was formed first. At the temperature around 1573 K, the eutectic reaction occurs where the liquid phase transforms to austenite and M 7 C 3 as shown in Fig. 12a. Iron (/ ˈ aɪ ər n /) is a chemical element with symbol Fe (from Latin: ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table.It is, by mass, the most common element on Earth, right in front of oxygen (32.1% and 30.1%, respectively), forming much of Earth's outer and inner core.It is the fourth most common … Cast iron is made from pig iron, which is the product of melting iron ore in a blast furnace. Cast iron can be made directly from the molten pig iron or by re-melting pig iron, often along with substantial quantities of iron, steel, limestone, carbon (coke), and taking various steps to remove undesirable contaminants.

Iron iron carbide phase diagram. H. K. D. H. Bhadeshia. A superalloy is a metallic alloy which can be used at high temperatures, often in excess of 0.7 of the absolute melting temperature. Creep and oxidation resistance are the prime design criteria. Superalloys can be based on iron, cobalt or nickel, the latter being best suited for aeroengine applications. Sodium hydroxide, also known as lye and caustic soda, is an inorganic compound with the formula NaOH. It is a white solid ionic compound consisting of sodium cations Na + and hydroxide anions OH −. Sodium hydroxide is a highly caustic base and alkali that decomposes proteins at ordinary ambient temperatures and may cause severe chemical burns.It is highly soluble in … the iron iron carbide phase diagram does not have a single microstructure, it has different microstructures depending on the carbon content of the steel. ... Here is a detailed description of the ... Cementite or iron carbide, is very hard, brittle intermetallic compound of iron & carbon, as Fe 3 C, contains 6.67 % C. It is the hardest structure that appears on the diagram, exact melting point unknown. Its crystal structure is orthorhombic. It is has low tensile strength (approx. 5,000 psi), but high compressive strength.

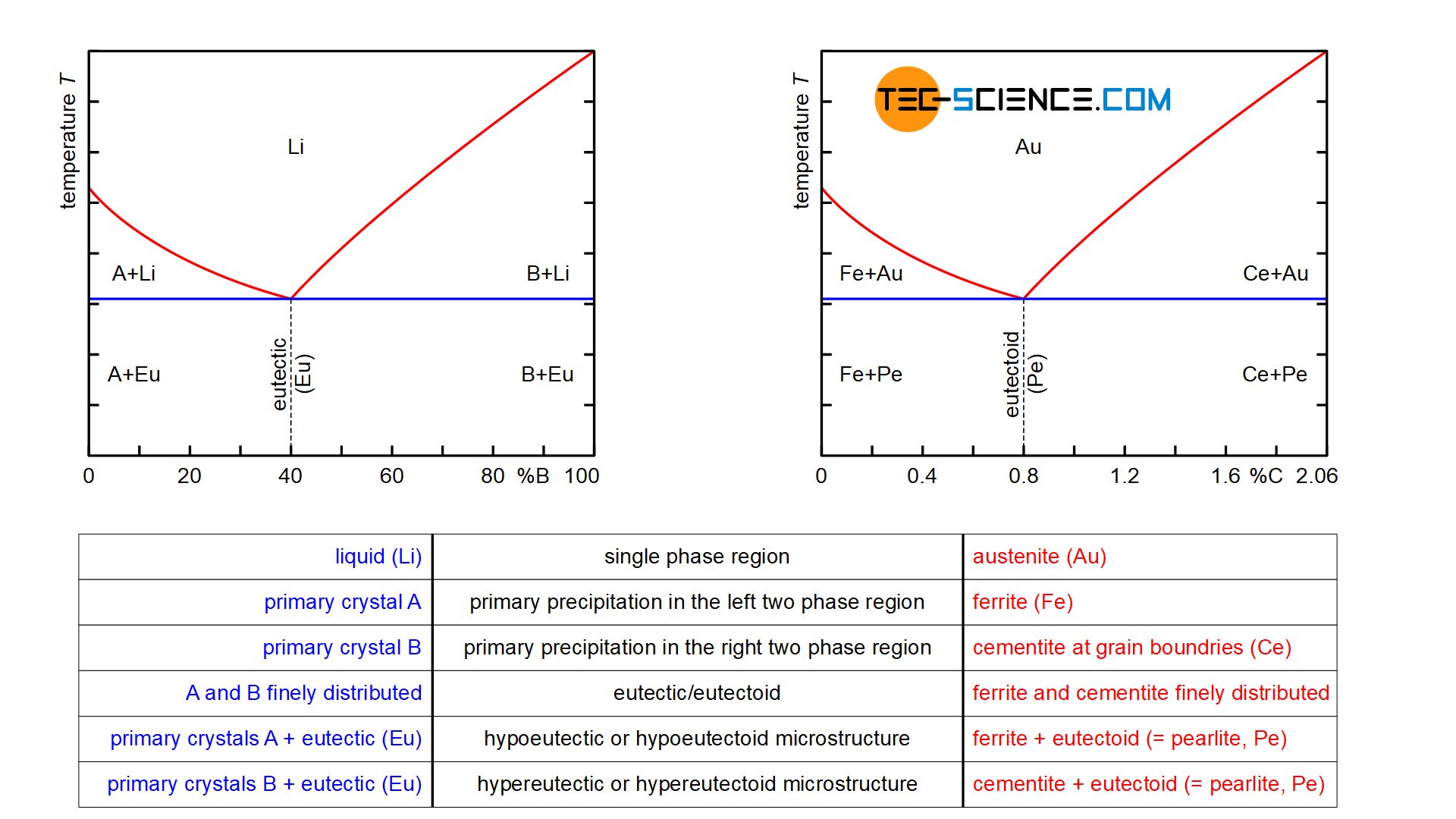

Binary phase diagram If a system consists of two components, equilibrium of phases exist is depicted by binary phase diagram. For most systems, pressure is constant, thus independently variable parameters are –temperature and composition. Two components can be either two metals (Cu and Ni), or a Example: Phase Equilibria For a 99.6 wt% Fe-0.40 wt% C at a temperature just below the eutectoid, determine the following a) composition of Fe 3C and ferrite (α) b) the amount of carbide (cementite) in grams that forms per 100 g of steel c) the amount of pearlite and proeutectoid ferrite (α) The iron–graphite phase diagram is similar in form to Fig. 3.21, with C (graphite) replacing Fe 3 C and it may still be used to account for the microstructures that develop. Hypoeutectic irons solidify to dendrites of austenite in an austenite/graphite eutectic, and hypereutectic irons form primary graphite flakes in the same austenite ... Important phases in Iron Iron Carbide Phase diagram has discussed in this video. Please subscribe to this our channel for more videos. #metallurgy #metallurg...

Jul 07, 2021 · Cast Iron is considered the most widely used metal-matrix composite from the 1920s. Follow microstructural development in Cast Iron types to learn about graphite nucleation mechanism, lediburite formation, and eutectic and eutectoid reactions within cast iron.. Cast Iron is being used in a wide area of industry i.e. boilers, water conduit pipes in Oil and Gas Industry. The Iron-carbon phase or equilibrium diagram is an overall study of iron, carbon, and their alloys and how they act under the various equilibrium conditions. In this blog, we studied these aspects of the equilibrium diagram and also how phase transformation depends upon the temperature conditions. The iron-iron carbide (Fe-Fe3C) phase diagram Microstructures of iron α- ferrite austenite. 2 Interstitial sites of FCC Interstitial sites of BCC. 3 Microstructure in iron-carbon alloys REutectic--pearlite Hypoeutectoid alloys. 4 Hypereutectoid alloys Equilibrium diagrams having intermediate phases or compounds Iron-Iron Carbide Phase Diagram | Material Engineering. The Iron-Iron carbide (Fe-Fe 3 C) is defined by five individual phases and four invariant reactions. Five phases are- α-ferrite (BCC) Fe-C solid solution, γ-austenite (FCC) Fe-C solid solution, δ -ferrite (BCC) Fe-C solid solution, Fe 3 C (iron carbide) or cementite – an inter ...

Cast iron is made from pig iron, which is the product of melting iron ore in a blast furnace. Cast iron can be made directly from the molten pig iron or by re-melting pig iron, often along with substantial quantities of iron, steel, limestone, carbon (coke), and taking various steps to remove undesirable contaminants.

Iron (/ ˈ aɪ ər n /) is a chemical element with symbol Fe (from Latin: ferrum) and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table.It is, by mass, the most common element on Earth, right in front of oxygen (32.1% and 30.1%, respectively), forming much of Earth's outer and inner core.It is the fourth most common …

Oct 21, 2021 · Fig. 12 shows the phase constitutions of two HCCIs with and without Ti during cooling. In the liquid phase containing Ti and C, the TiC phase was formed first. At the temperature around 1573 K, the eutectic reaction occurs where the liquid phase transforms to austenite and M 7 C 3 as shown in Fig. 12a.

0 Response to "39 iron iron carbide phase diagram"

Post a Comment