34 radiant heat mixing valve diagram

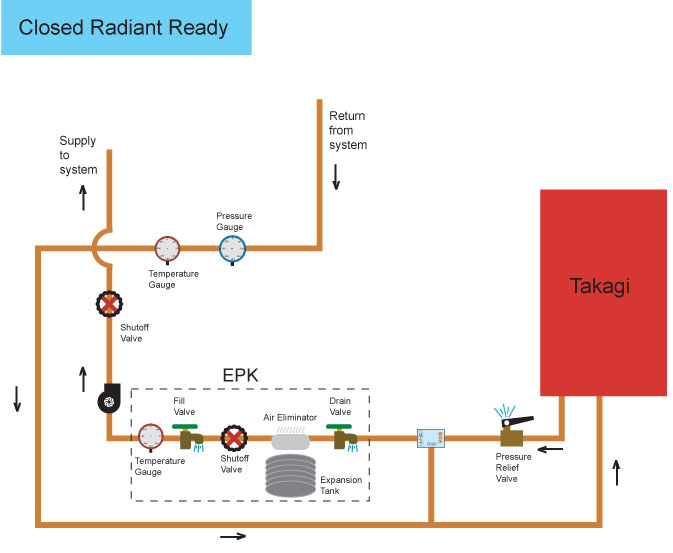

The Do's. Do #1. Pump away from expansion tank. This has to be one of the most frequently emphasized details of modern hydronic heating. It still amazes me how it faded into semi-obscurity, especially its use on smaller systems, between when it was first postulated in the 1950s, and when it was "rediscovered" by the hydronics industry a few years ago (thanks largely to the efforts of Dan Holohan).

valve opens and closes to provide injection mixing/reset to radiant. Radiant circulator overcomes headloss through valve, injection piping. Globe valve needed on RFH bypass piping to provide pressure drop to encourage water to return to primary when RFH circulator is running. • Size the following: - 30,000 BTUH radiant, 100 ΔT

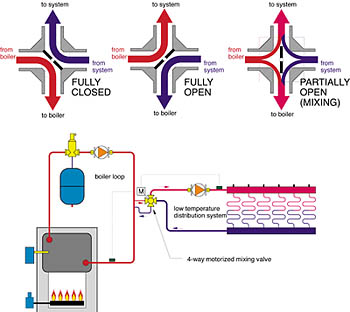

Ordering Code: 722. UPC: 779655072201. 4-Way Mixing Valve, 1 1/4 IN Brass. The 4-Way Brass Mixing Valve 722 is used to mix supply water from a hydronic source with water returning from a system. It is designed for use in either closed loop or open loop hydronic systems. This 4-way valve has standard female NPT threads, as well as a maximum leak ...

Radiant heat mixing valve diagram

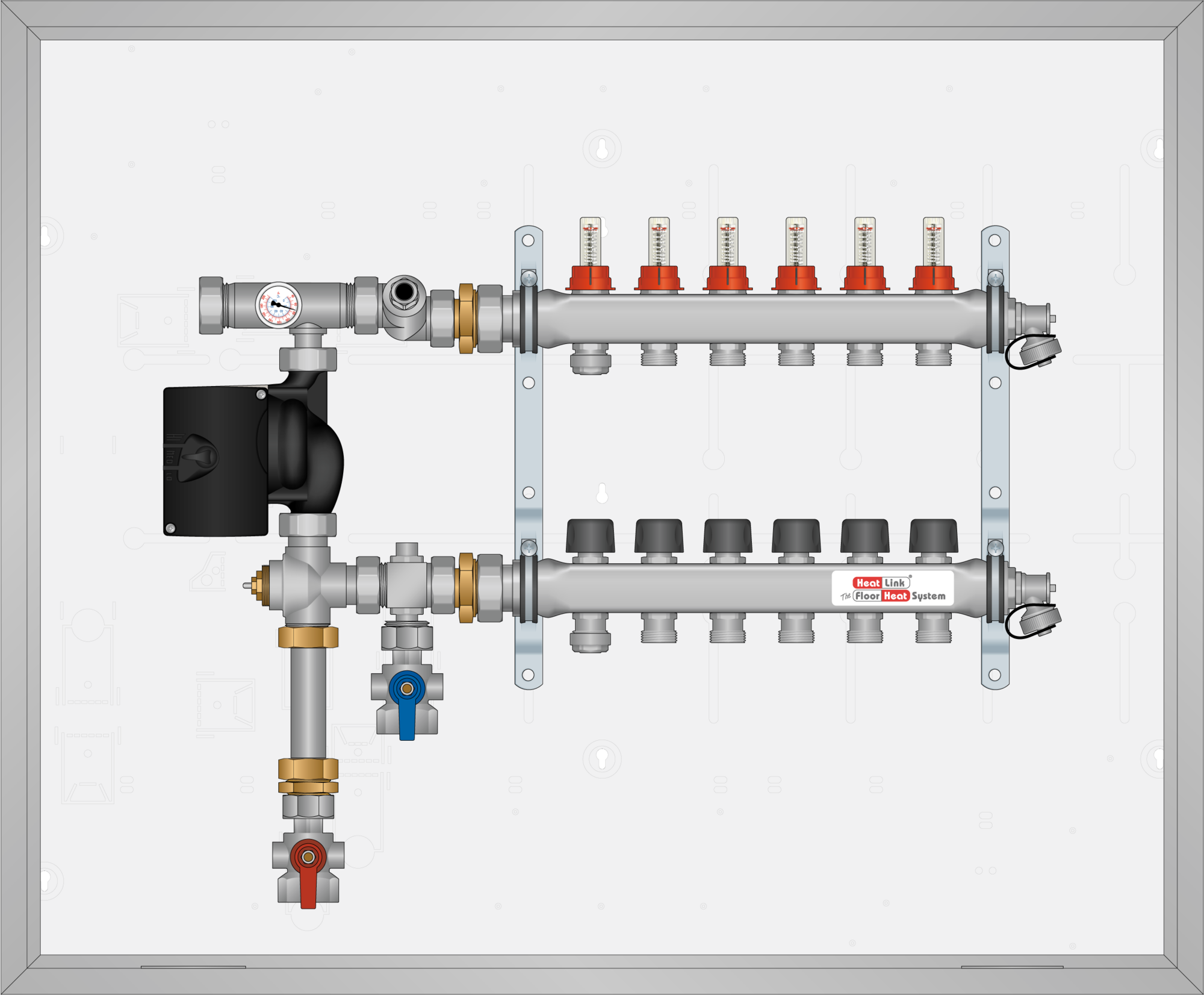

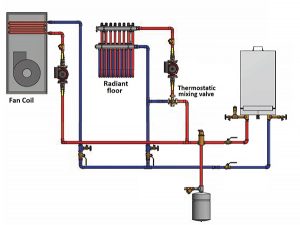

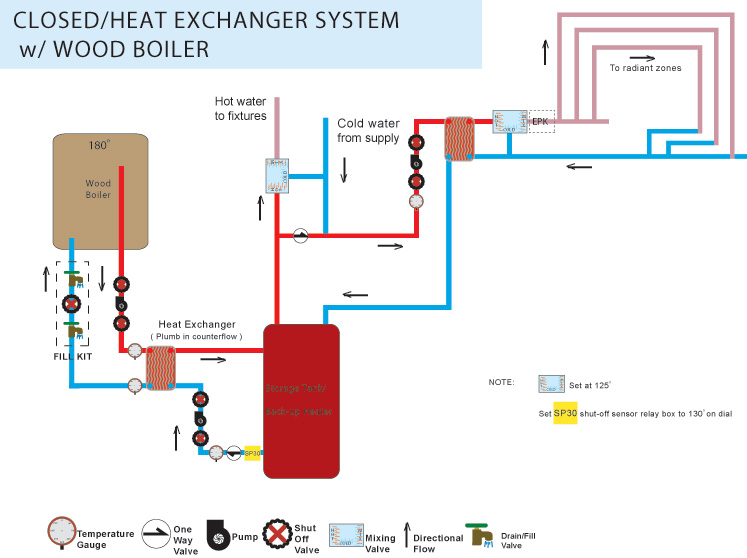

Heat Exchanger Thermostatic Mixing Valve A pump must be installed in the hot supply line between the outdoor furnace and thermostatic valve. Hot Supply from Pump ... System Diagrams Radiant Heat Multi Zone In-Floor 71 73 75 80 86 102 76 67 65 Forced Air vs. Radiant In-Floor Insulation Closed-cell Polystyrene Thermal Insulation OUT IN

Mixing Methods with Radiant Heating Systems. Written on: September 1, 2019 by George Carey. When designing a radiant heating system, it becomes obvious that this system has characteristics different from the conventional baseboard-type of heating system. One quick difference is the temperature of the water circulated through the tubing.

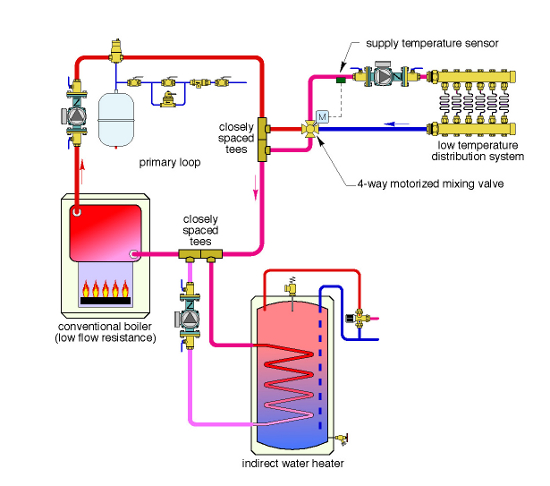

On the supply side of the radiant coming out of the 4 way mixing valve, you would have a 2nd pump to pull heat out and push it into the radiant piping (a fixed speed pump like a grundfos 15-18, probably on low or medium speed would fit the bill here as you don't have much radiant to worry about).

Radiant heat mixing valve diagram.

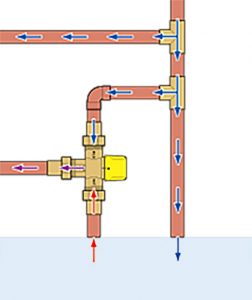

Tips for properly installing these mixing valves in radiant heating systems. One of the best known temperature control devices in hydronic radiant heating systems is the three-way thermostatic mixing valve. It's available from several manufacturers with either an internal thermostatic element or an external actuator.

Radiant Heating 101: Mixing valves and controls for in-floor radiant heating A solid control apparatus is the cornerstone of a well-designed in-floor radiant heating system. The chief function of a control system is to modulate and limit water-temperatures to maximize efficiency and to insure against over-heated floors.

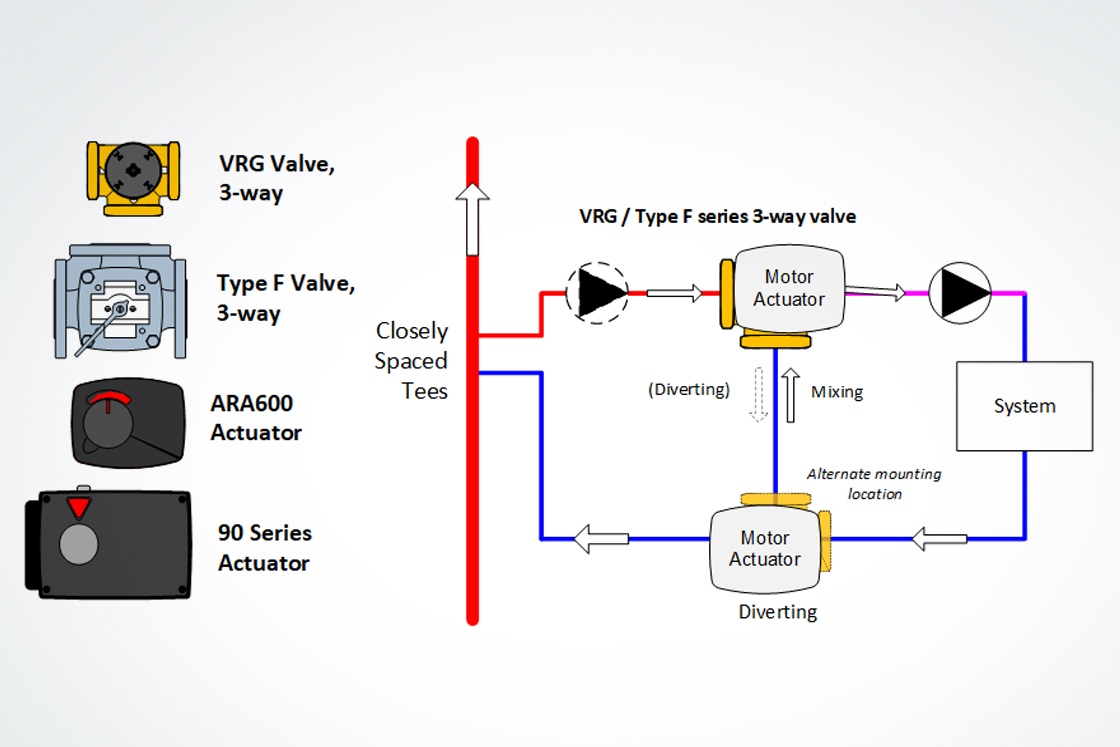

• Assemble the actuator/motor and the valve. Then wire the Actuator to the heating control. 3-Way Motorized Valve Overview The 3-Way Motorized Valve can be used in a variety of applications. This manual will describe its use in heating applications only. Mixing In radiant applications, 3-way motorized valves can be used to mix the hot water ...

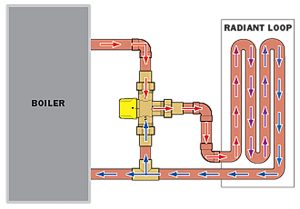

A mixing valve is pre-installed in this type of manifold. The baseboard or cast iron radiator zones, for example, receive super hot water straight from the heat source. The much cooler radiant floor zones receive tempered water from the "mix" port of the mixing valve. The schematic below illustrates this approach.

thermostatic mixing valves are designed to do. For every JoB Our Apollo® family of mixing valves includes ASSE certified products to meet all your point-of-source and point-of use requirements. We also offer a full range of non-ASSE models designed specifically for the higher temperatures associated with hydronic and radiant heating systems.

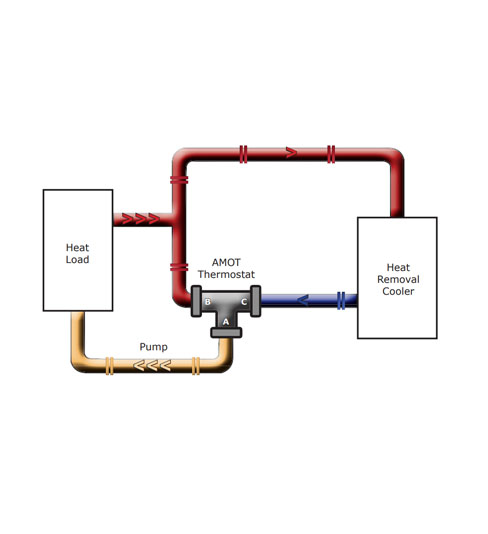

Variable Speed Injection Mixing uses a circulator as a mixing device instead of a 2-way,3-way or 4-way valve.Typically used in radiant primary/secondary piping designs, the variable speed pump is installed in the "bridge" piping (see Figure 1)

Page 6 1-800-872-7277 · www.zurn.com Zurn Radiant Heating Design and Application Guide Radiant panel heating increases our comfort in many ways. For example, radiant floor heat has more even floor-to-ceiling temperatures than other

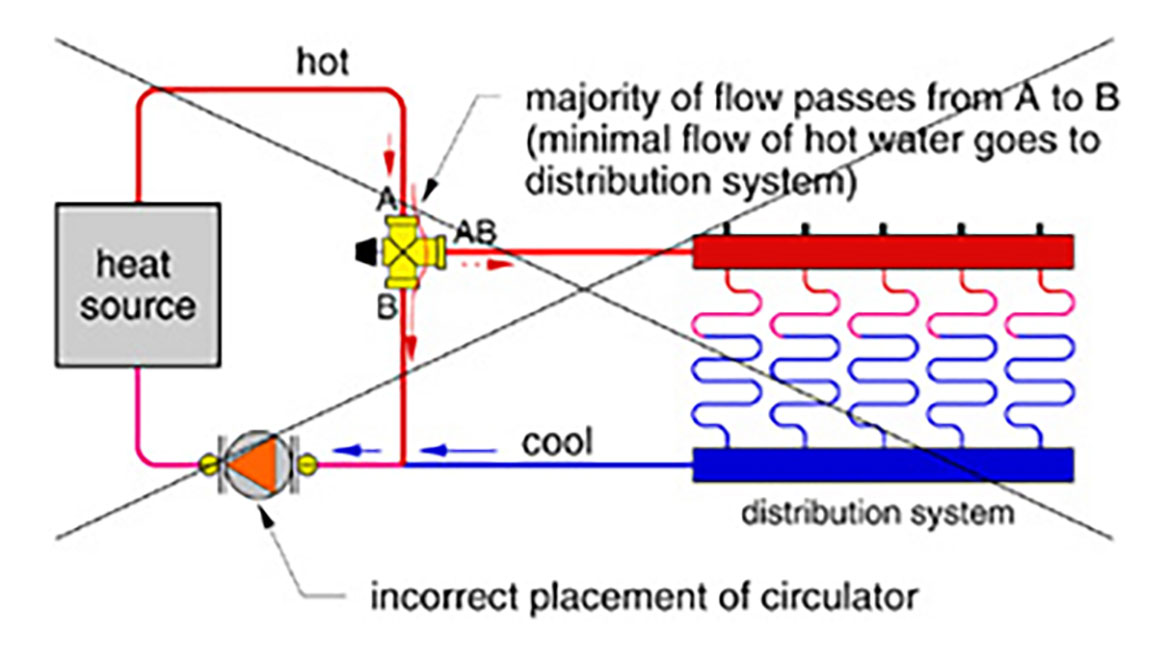

Now consider that mixing valve used to control the temperature being fed to -- let's say a radiant loop. The hot inlet is connected to a manifold or to a boiler. The cold inlet is connected to the return from the loop through a T. How do we get it so that the outlet has a lower pressure? Well, on the hot side that shouldn't be a problem.

loss and may equal 6,000 to 9,000 BTUH. Any heat exchanger used to heat a hot tub should be sized for this larger value. RADIANT FLOOR HEATING: Normal temperature drop is 10°F to 20°F per tube length. Try not to exceed a floor surface temperature of 85°F (comfort and finish materials limitations).

In this excerpt from his Classic Hydronics seminar, Dan Holohan shares his knowledge about mixing low-temperature radiant heating with a higher-temperature h...

Radiant heat mixing valve diagram. The much cooler radiant floor zones receive tempered water from the mix port of the mixing valve. The baseboard or cast iron radiator zones for example receive super hot water straight from the heat source. Mixed supply setpoint can be configured to reset from the outdoor air temperature.

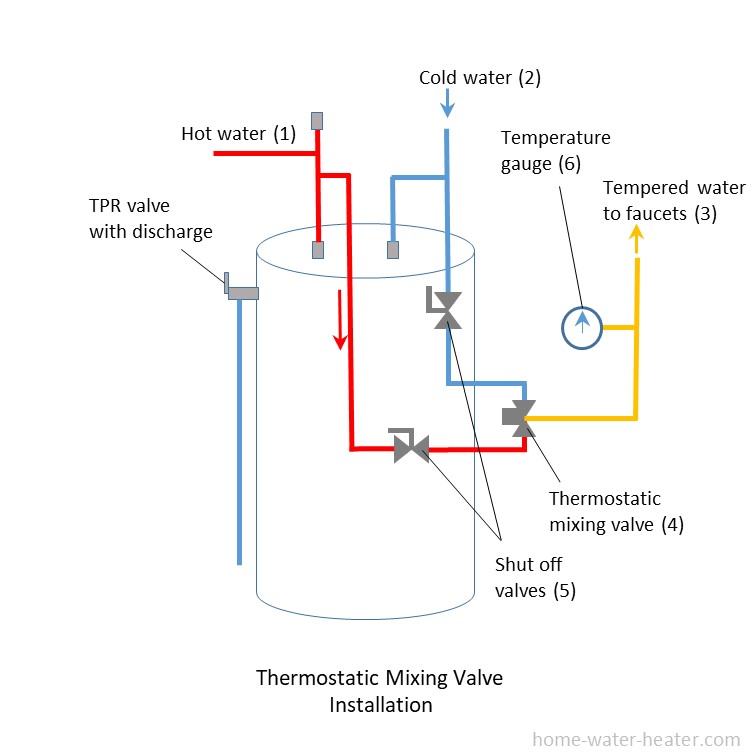

Thermostatic mixing valves are used in residential, commercial and institutional applications for both plumbing and hydronic heating. The primary function of these valves is to control the output water temperature to either a domestic hot water supply system, or provide a low temperature supply to a radiant floor heating system.

Shop our products: https://pexuniverse.comAbout PEX Universe:PEX Universe (aka PEX-U) is a leading industrial equipment supplier offering high quality heatin...

Thermostatic mixing valve. 25-50°C 40-70°C 167 series Code: 167032 167042 Technical Brochure: 01239 Three-way valve with sector obturator and three point actuator. RH LH 165 series Code: 165001 Mounting bracket in stainless steel. 519 series Code: 519006 Technical Brochure: 01237 Differential by-pass valve, setting range 0,2-3 m w.g..

INFLOOR HEATING SYSTEM oor® Heating Systems er the customer and dealer various options when selecting a radiant heating system . I oor's Residential / Light Commercial Systems include copper manifolds, brass manifolds, mixing valves and related controls, zoning cotrnols with domestic hot water priority, pre-piped and

The first part contains a general overview of radiant heat and it's various applications. All the necessary components of a well-engineered and efficient hydronic radiant floor system are explained in a straight forward and non-technical manner. The second section gets down to the nitty gritty details of ... Mixing Valve Secondary loop In. 50 ...

For the heat load that the Warmboard can handle, this computes to a Delta T of somewhere between 7 to 13 degrees. For the mixing valve I need one rated for mixing at a low flow because my single loop dictates the total flow rate, and that is why I am looking at the Honeywell AM101R-US.

of the mixing valve circuit to be adjusted to the respective conditions. Heating curves: Low temperature heating system, e.g. radiant floor heating Medium temperature heating system, e.g. cast iron radiation, staple-up radiant floor heating High temperature heating system, e.g. fintube radiation, fan coils The maximum boiler water temperature is

Radiant Heat Mixing Valve Diagram. Piping Schematic. Level I Control. • Modulating-condensing boiler. • Dual- temperature radiant floor heating. • Three-way tempering valve. Where: Multiple. Best practice is to pump away from the mixing valve, not into it. We sometimes hear about a pump discharge being piped to the hot inlet of a ...

Three-way Mixing Valve Installation Guide 1 Introduction The Uponor Three-way Mixing Valve (A3040075, A3040100) is a microprocessor-controlled valve designed to regulate the supply water temperature to a radiant heating system by modulating the position of the valve. Mixed supply setpoint can be configured to reset from the outdoor air temperature.

Mixing valves used for radiant have three (sometimes four) ports; basically, one port accepts the hot water directly from the boiler supply, the second port accepts cold water from the returning loop, just before it goes back into the boiler, & the 3rd port COMBINES the hot & cold to produce water at ~100 degrees to supply the in-floor radiant loop.

Thermostatic Mixing Valves are for controlling water temperatures in PEX radiant floor heat, Solar Hot Water Heating and other hydronic applications. Taco Power Mixing Valves are also for solar hot water tanks when needed to reduce water temperature to safe levels for home use. Caleffi Thermostatic Mixing Valves for hydronic and potable water ...

My question is related to this topic and it is about the following code: "607.2.2 Piping for Recirculation Systems Having Master Thermostatic Valves: Where a thermostatic mixing valve is used in a system with a hot water recirculating pump, the hot water or tempered water return line shall be routed to the cold water inlet pipe of the water heater and the cold water inlet pipe or the hot water ...

0 Response to "34 radiant heat mixing valve diagram"

Post a Comment